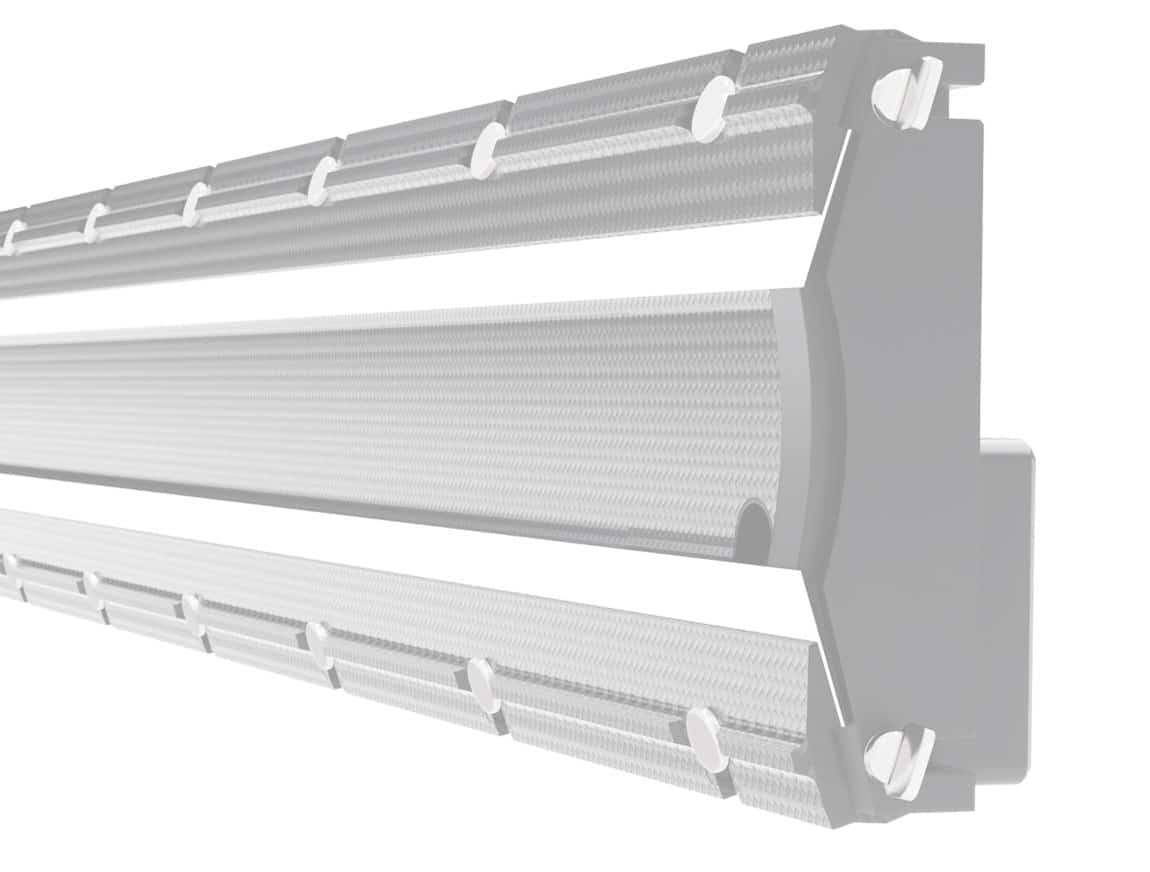

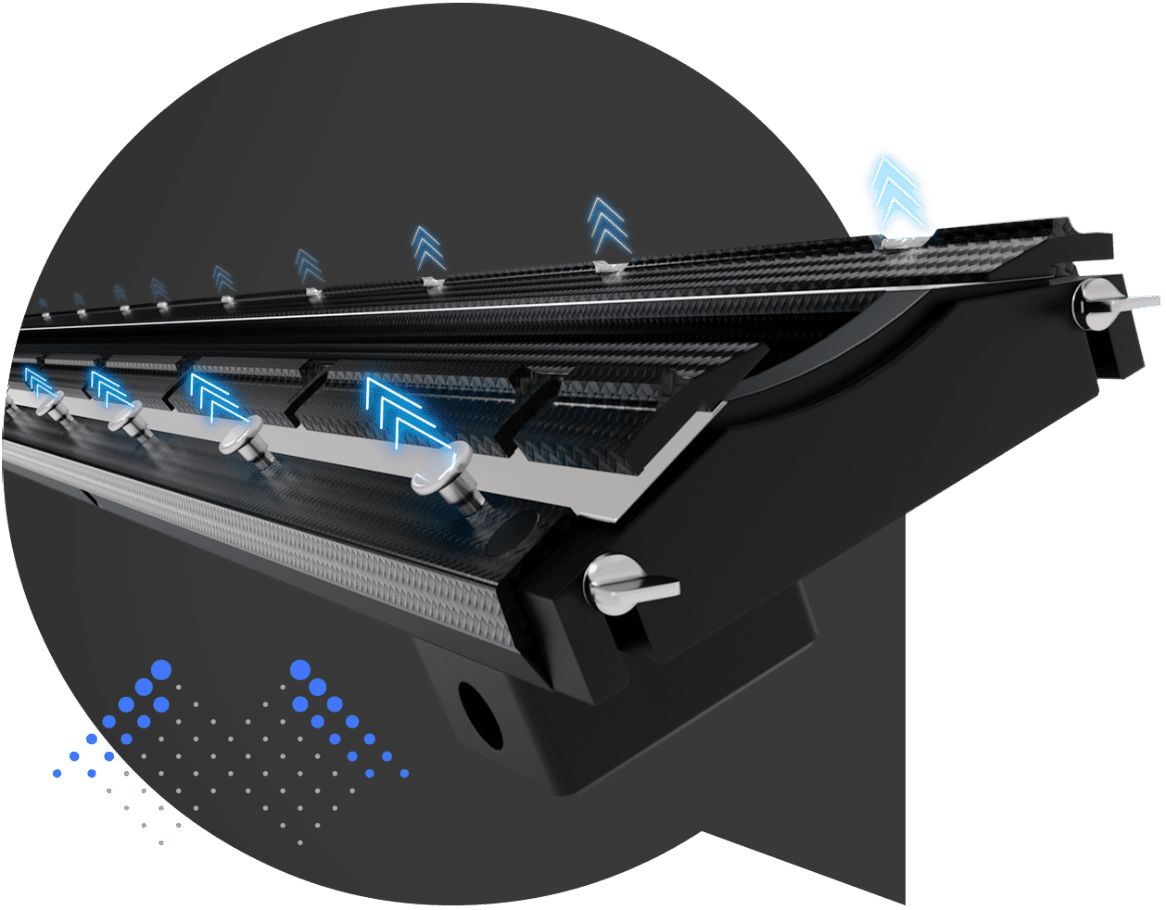

Absolute Engineering has made significant progress in installing their unique woven carbon fiber chambers.

Absolute Engineering has made significant progress in installing their unique woven carbon fiber chambers on post printers over the last 12 months. Great Northern Corrugated (GNC) originally installed 3 units on their Ward before proceeding to upgrade their United Flexus.

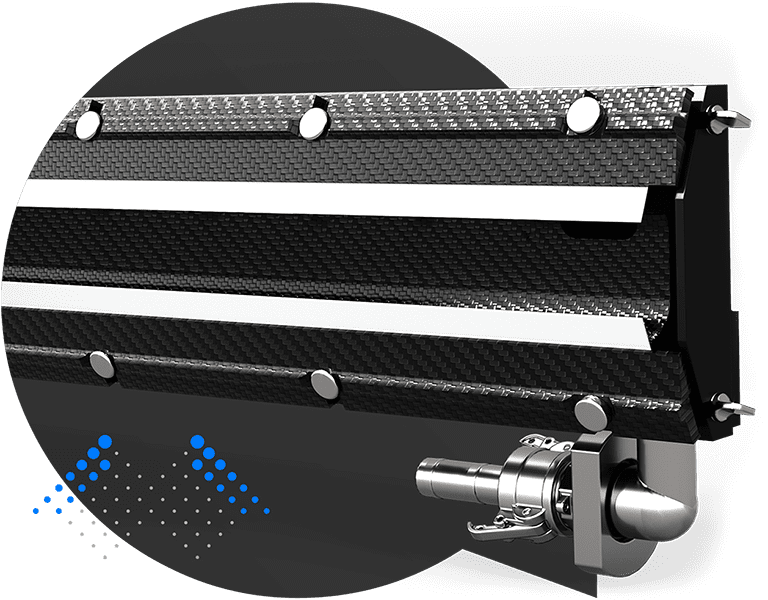

Bob Smith of GNC Racine commented “We can now run many of the jobs we used to skip-feed on regular feed. The doctor blade change has gone down from 30 minutes to 5 minutes, and because of the make-up of the chambers, cleanup is now an actual clean-up, the ink slides off with minimal effort … the crews absolutely love them. I would recommend these chambers with 100% confidence.”

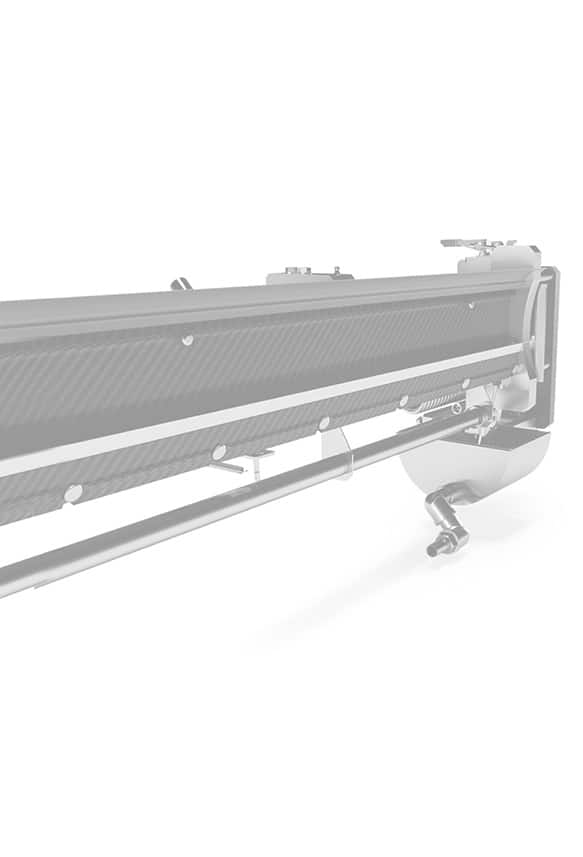

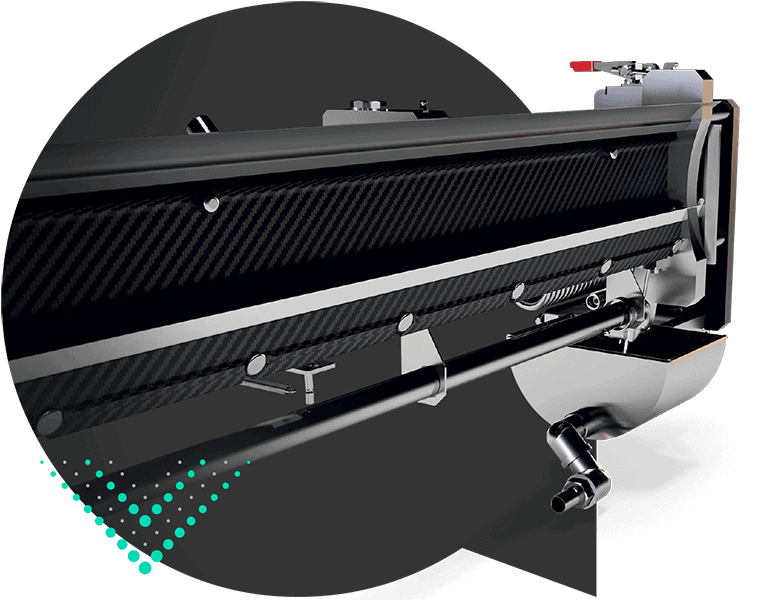

Absolute has also achieved considerable success with BOBST/Martin upgrades, including NT1628, NT1636 and 924 print units.

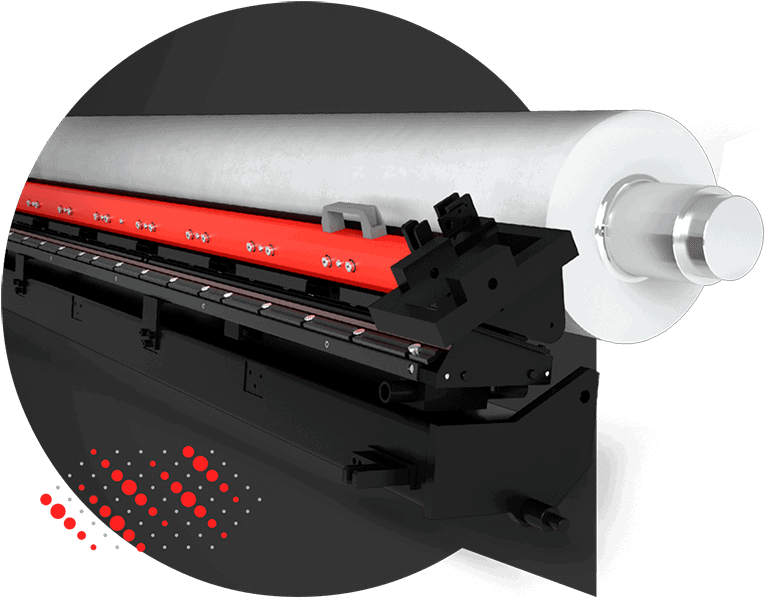

Rick Young, Absolute’s agent in North Central USA, is delighted with the momentum generated. “We have several customers who originally upgraded just existing equipment, but have now started specifying them on their new equipment.

This proves that Absolute chambers can give quantifiable benefits over traditional chambers”

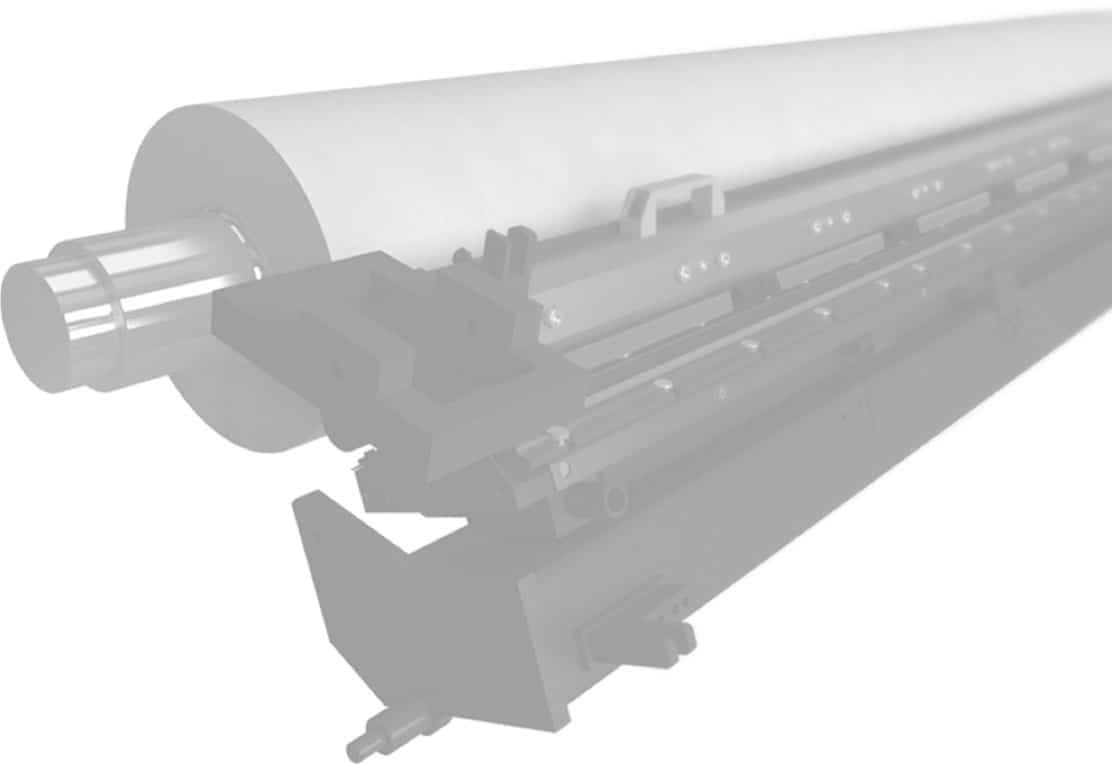

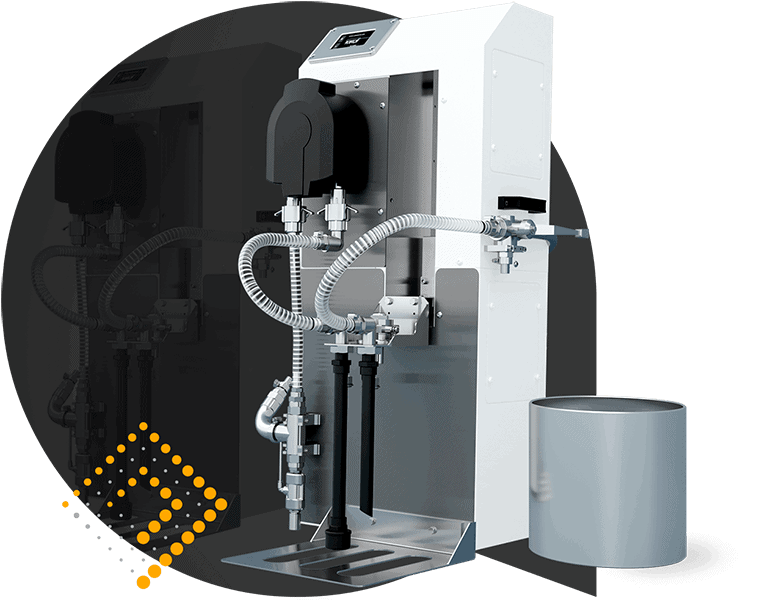

Absolute have recently moved to a new factory in order to meet the increasing demand.

The plant includes test facilities to complete development of a new range of upgrades specifically for Corrugated. These new options will provide even more opportunities to generate cost reductions for any customer using current chamber technology.