Thinking differently

Ultimately Absolute

At Absolute, we know that the best technical products don’t just need the best technical minds to develop and build them. They need holistic creative thinking too. That’s why ours is a different way of doing things.

The Absolute Ethos

Led by design, followed by rivals

Digging deep into assumptions

As engineers, we’re obsessed with design. After all, without great design at its heart, a product will never fulfil its performance potential.

Our projects begin with one simple question: how do we design the very best solution to this challenge? Finding the answer requires us to question assumptions and take risks too, as well as perform meticulous research, design and prototyping. It’s a process that never really ends. That’s because as new technologies and materials emerge, so our designs evolve to embrace them. That’s why our products are always out in front.

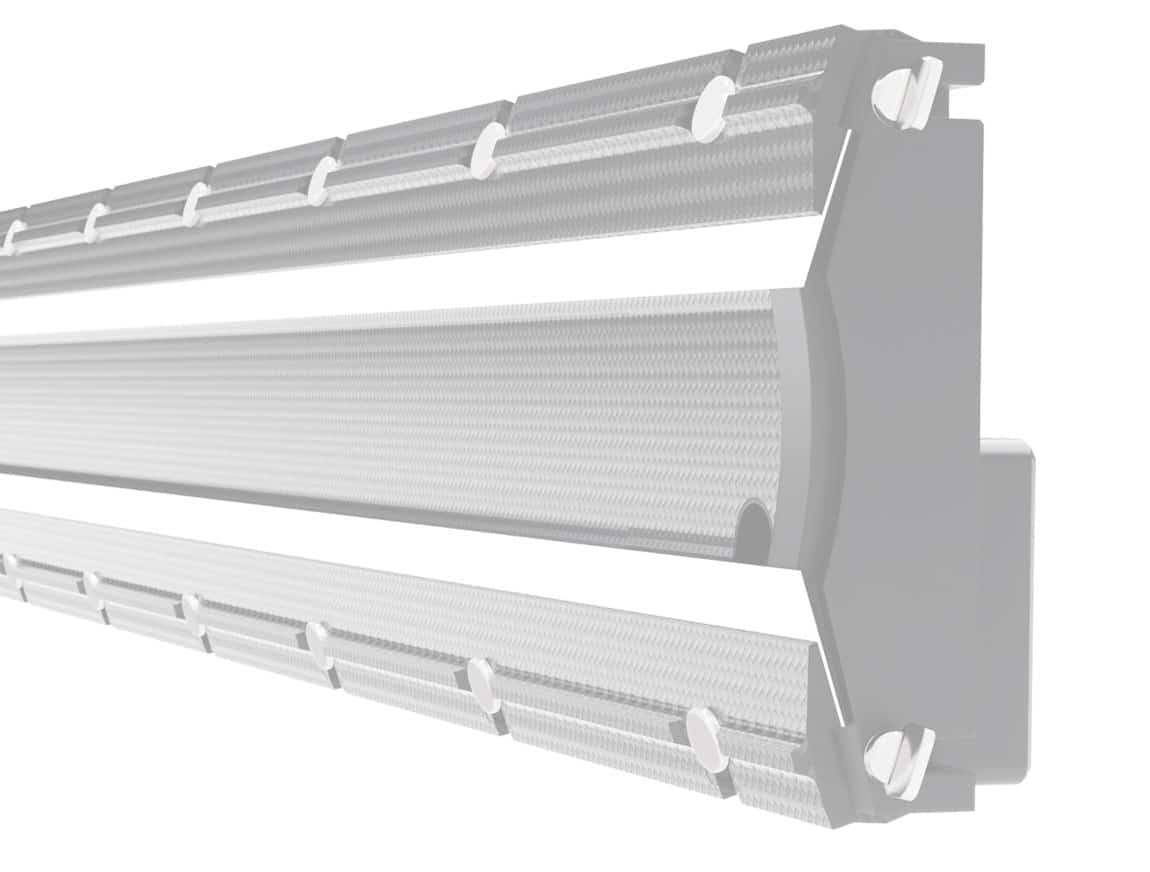

Built to last, and last, and last…

Building products that outperform their rivals is great. What really sets us apart is that ours outlast them too. From our design ingenuity and intelligent material choice to ruthless testing in real-world conditions: nothing gets left to chance. For example, offering a 15-year anti-corrosion warranty on our Chamber3 and UniBlade2 products reflects our confidence. That no customer has ever made a claim: that’s just fact. Overall, it means better long-term value over every product’s lifespan, not to mention less waste, hassle and impact on the planet.

Wave goodbye to waste

We hate waste. With a passion. As everyone in our industry knows, whether it’s time, energy, materials or money, waste is the enemy of profit and a threat to our environment. That’s why minimising it is an ongoing mission right at the heart of our business. From the way we cleverly design wastage out of every product to the choices we make in our everyday operations – efficiency rules at Absolute.

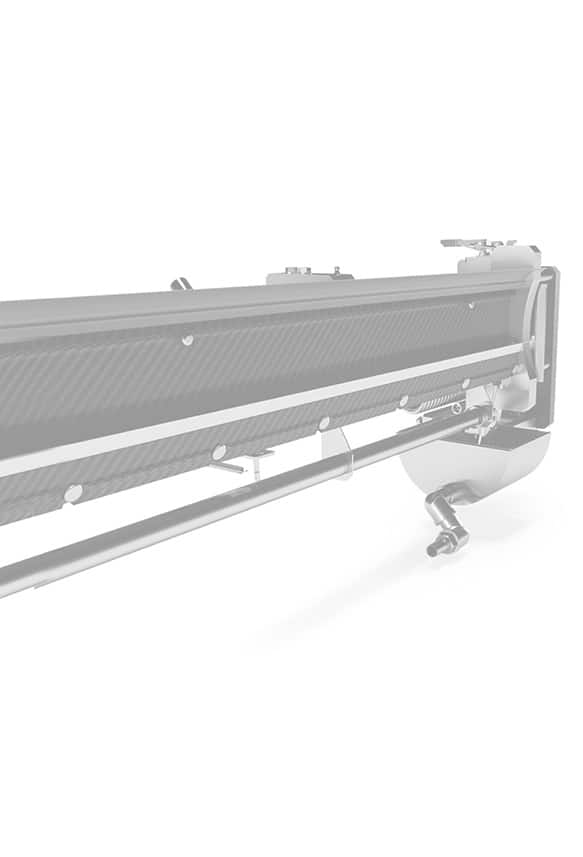

Profit down the drain

Where is the logic of making ink and then flushing it down your drain?

Quick and easy to use, our unique InkSave product doesn’t just reduce the amount of ink you waste; it slashes it by 80%. On top of that, its innovative system preserves your residual ink’s pigment and viscosity, so your very first box off the printer is saleable. Even your water waste is halved.

Discover:

*Typical ink loss on an average post printer with InkSave fitted is 600ml.

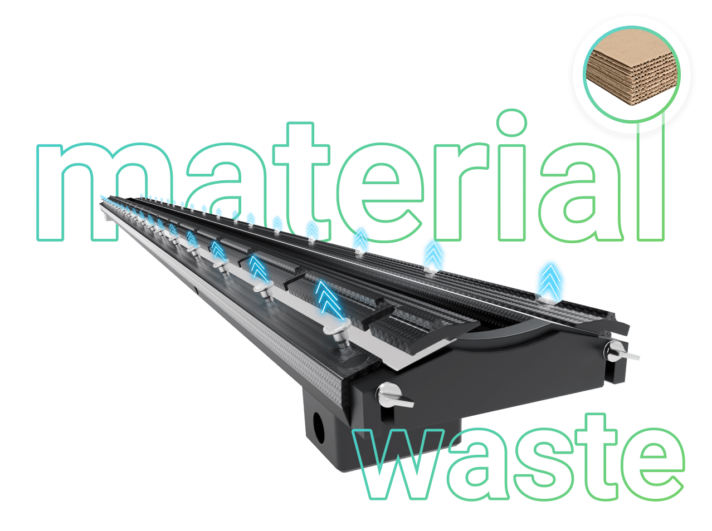

Material gains

Designing your ink circuit to avoid retained wash water means first box saleable. Why produce waste just to check for colour density?

Patented technologies like TrueBalance give our products a measurable edge in printing performance. Meanwhile, the sheer range of types and sizes of system we can work with means we’ve always got the perfect product for yours. It’s a winning combination, delivering minimal errors, consistency you can count on, and cutting your material wastage.

Discover:

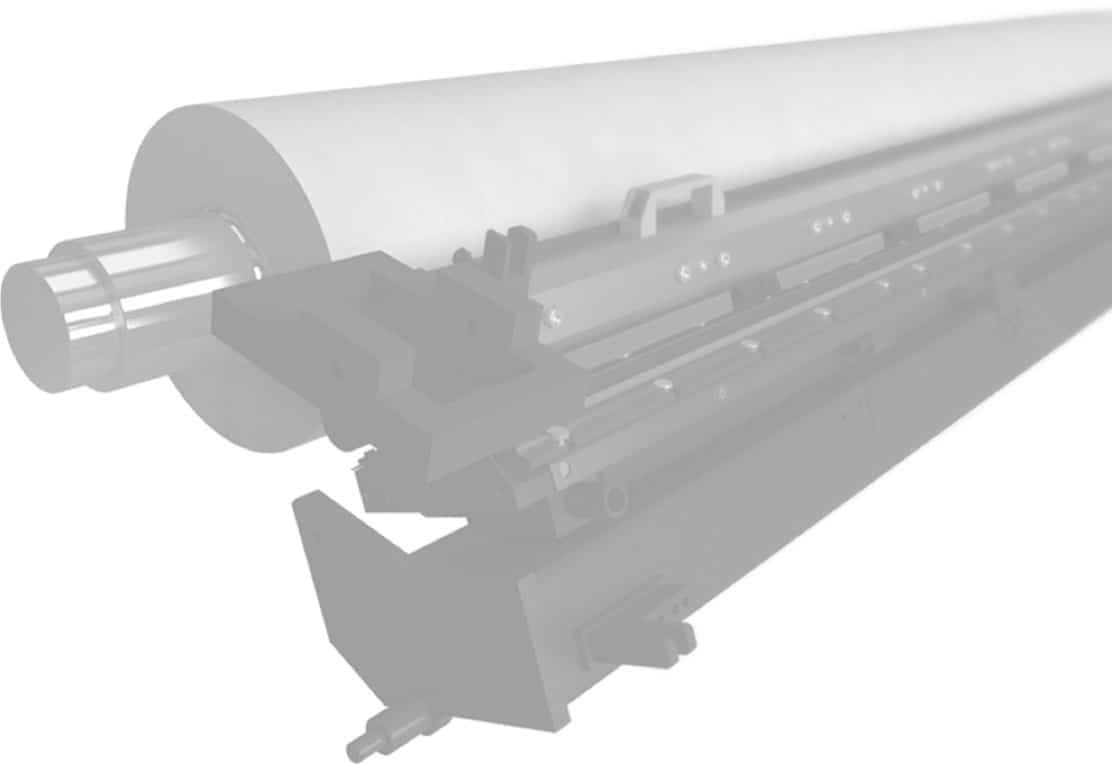

Call time on downtime

Imagine NEVER having to stop a job because your anilox is dirty and your colour density is wrong. Sono can clean every anilox whilst your machine is in production. Deskilled. De-stressed. Damn good.

Discover:

Being smart with energy

Putting more energy into using less of it

Small steps towards big change

To shrink environmental impact and keep product costs down, we’re always on the lookout for ways to minimise energy use. This has led to our more energy-efficient carbon fibre range which uses more energy-efficient carbon fibre engineering whilst saving on cost and still maintaining our 15-year guarantee. We machine our own stainless steel components too which helps cut down our air miles as well as gives us total control over quality.

Individually these might seem like small moves, and, in all fairness, they are. But together they add up to a much brighter bigger picture: a whole new approach built on holistic innovative thinking. It results in better products, longer-term value, and significantly less risk to our planet.

"The replacement chambers fitted to our Astraflex presses are working well making handling and blade changes a great deal safer with the reduced weight and easy operation. The biggest gain for us has been the reduction in blade bounce/chatter and the improved life of the blade (given that we now run with reduced bar pressures down at 1-2 bar) we have seen improvement with ink voiding and starvation with the new chamber."

Matt Duncan, Print Value Stream Manager

Matt Duncan, Print Value Stream ManagerAmcor Flexibles Evesham