Sono: The product

The world’s first on-press

ultrasonic anilox cleaner

Smart. Consistent. Fast

Take control of ink and colour management on your flexo. There’s never been an on-press anilox cleaner capable of 100% cell retrieval – until SONO.

As the world’s first and only ultrasonic on-press cleaner, SONO changes everything. In fact, anilox cleaning will never be the same again. Now you can control the heart of your flexo station and guarantee your customers the consistent colour management they insist on.

On-press speed and safety

SONO works on-press, so there’s no need for painfully slow and potentially dangerous anilox roller removal, and you don’t need the team of Maintenance Engineers to do it.

Think about it: all that time, equipment and health & safety risk that comes with preparing your rollers for cleaning, all gone. Because rollers are cleaned by print operatives in-situ, there’s no chance of damaging them. No maintenance crew involvement, and no forklifts, docking units, carrier trolleys or hoists. It’s just one more way SONO helps reduce the everyday challenge of running your flexo smoothly.

Your roller stays installed

SONO is on-press so there’s no need to remove your roller for cleaning which prevents potential costly damage.

Sono SmartGuide docking technology

SONO’s lightweight design and SmartGuide docking system means that just one operative can perfectly install SONO on-press for every clean.

Ultrasonic. Ultra-fast

Having dirty anilox cells is the biggest cause of defects in flexo, and it leads to manual intervention. Adjustments to ink are hugely expensive both in material terms and lost output, so how can you win back capacity in your plant at no cost? Simple: by controlling colour so that the norm is right first time, on-press and on-colour.

With SONO, this becomes the reality, and the payback in terms of increased ‘no cost’ capacity is huge. After all, print line downtime kills productivity. When it comes to maximising your machinery’s runtime over weeks, months or years, nothing comes close to SONO.

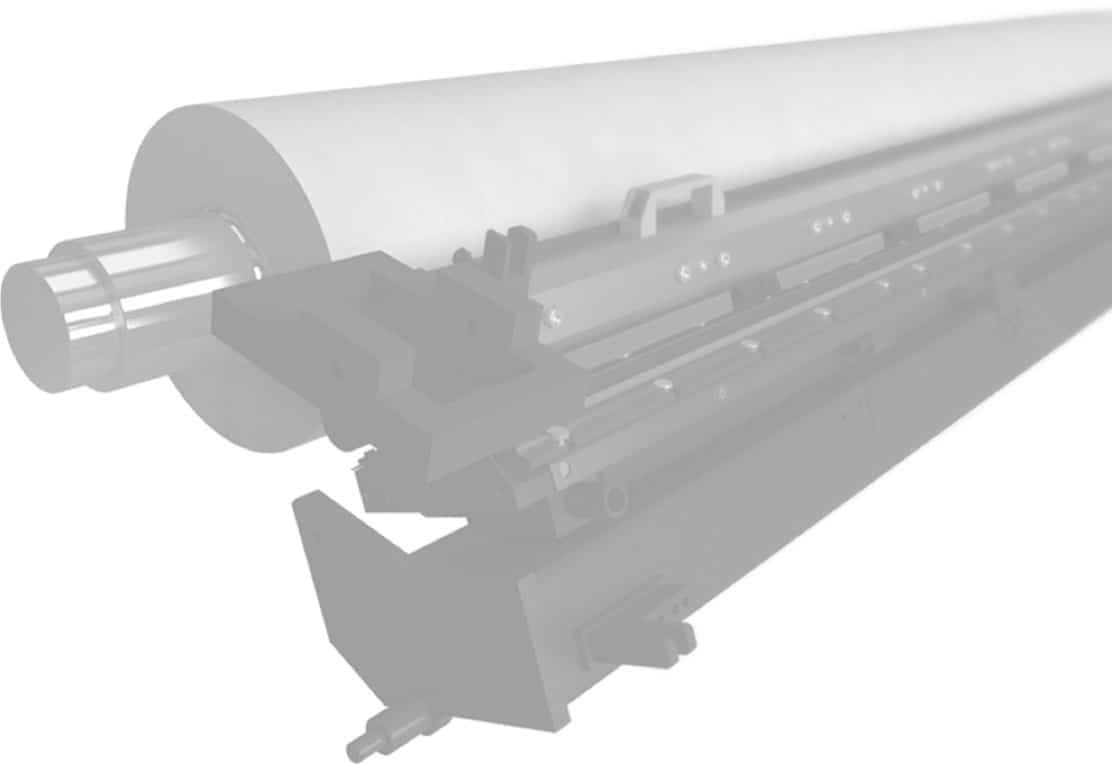

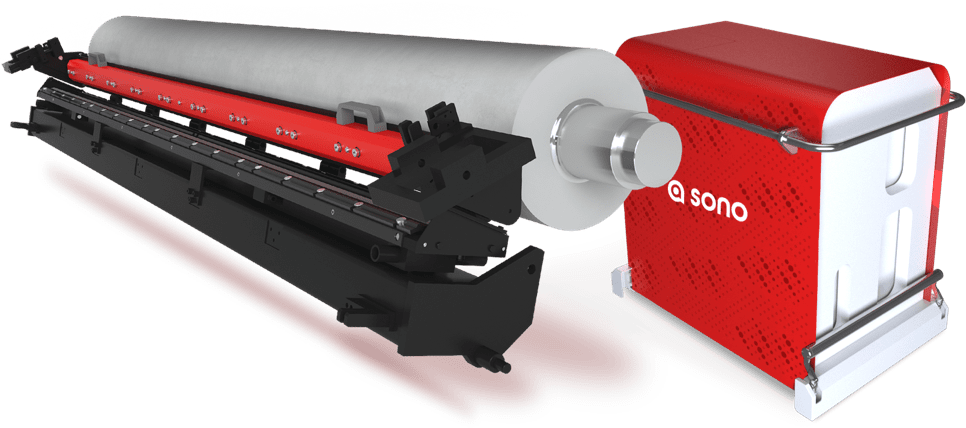

Sono consists of three components

Pod Console

This component is the brains of Sono, it incorporates the generators for the ultrasonics, the pump, the control system, the cleaning solution and dosing systems, all the technology and sequencing information to allow the Sono bar to meet your requirements.

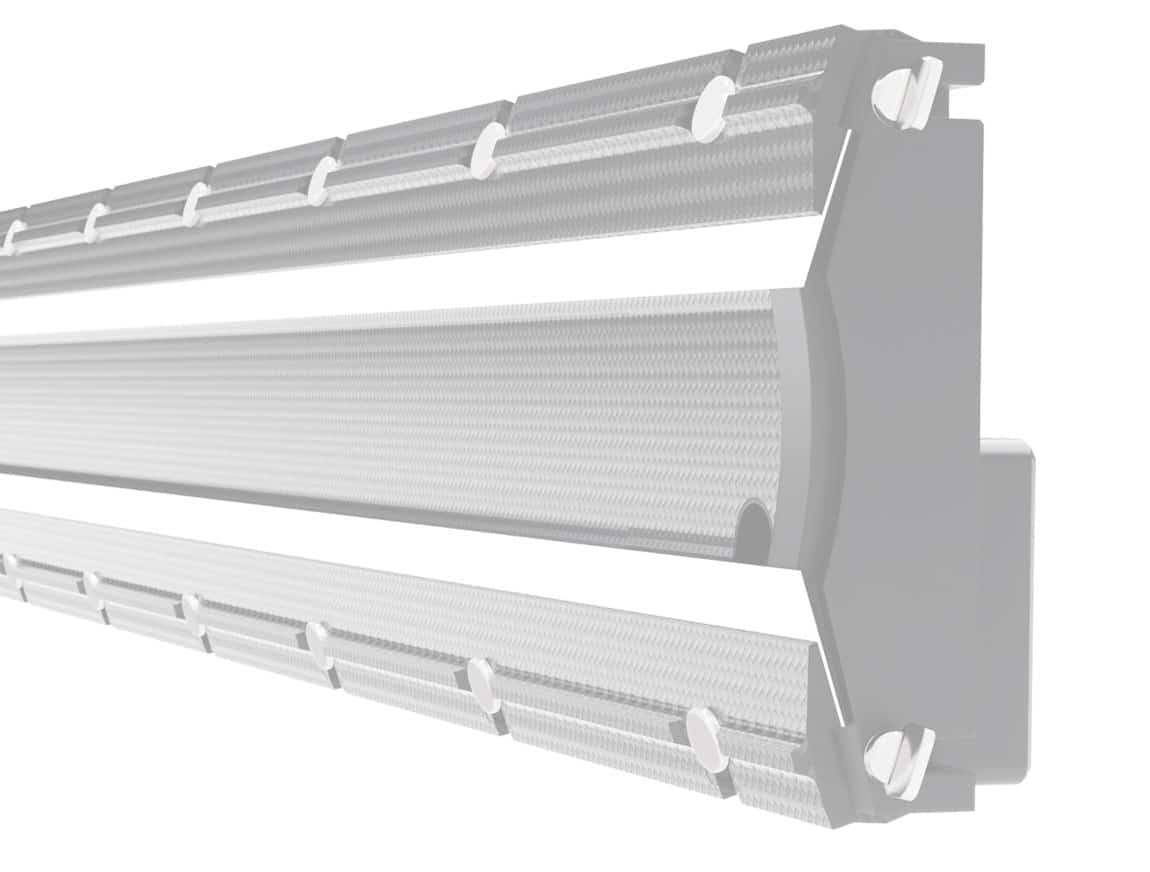

Sono

This component contains the ultrasonic transducers mounted to the cavity that encapsulates the solution to clean the anilox roller 100%.

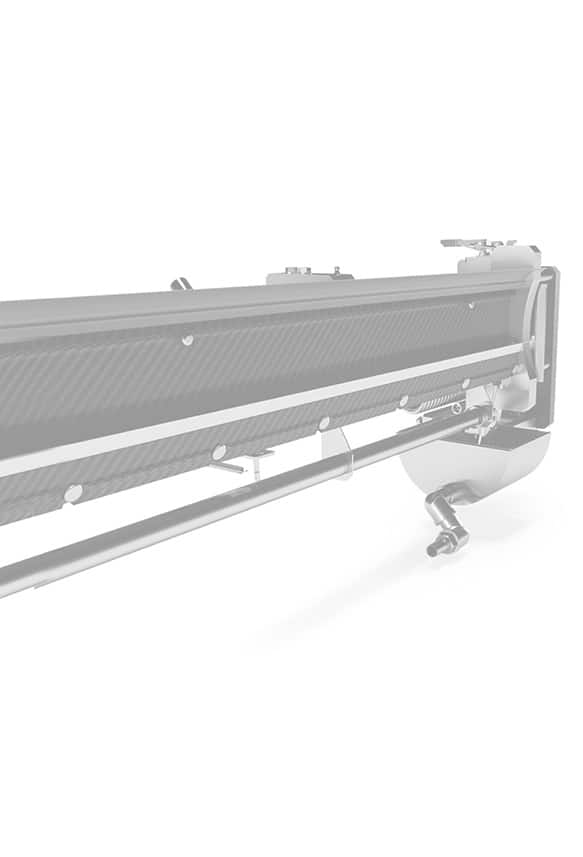

Smart Guide

Absolute’s unique docking system ensuring perfect location of Sono against your anilox, and designed specifically to complement each individual print unit.

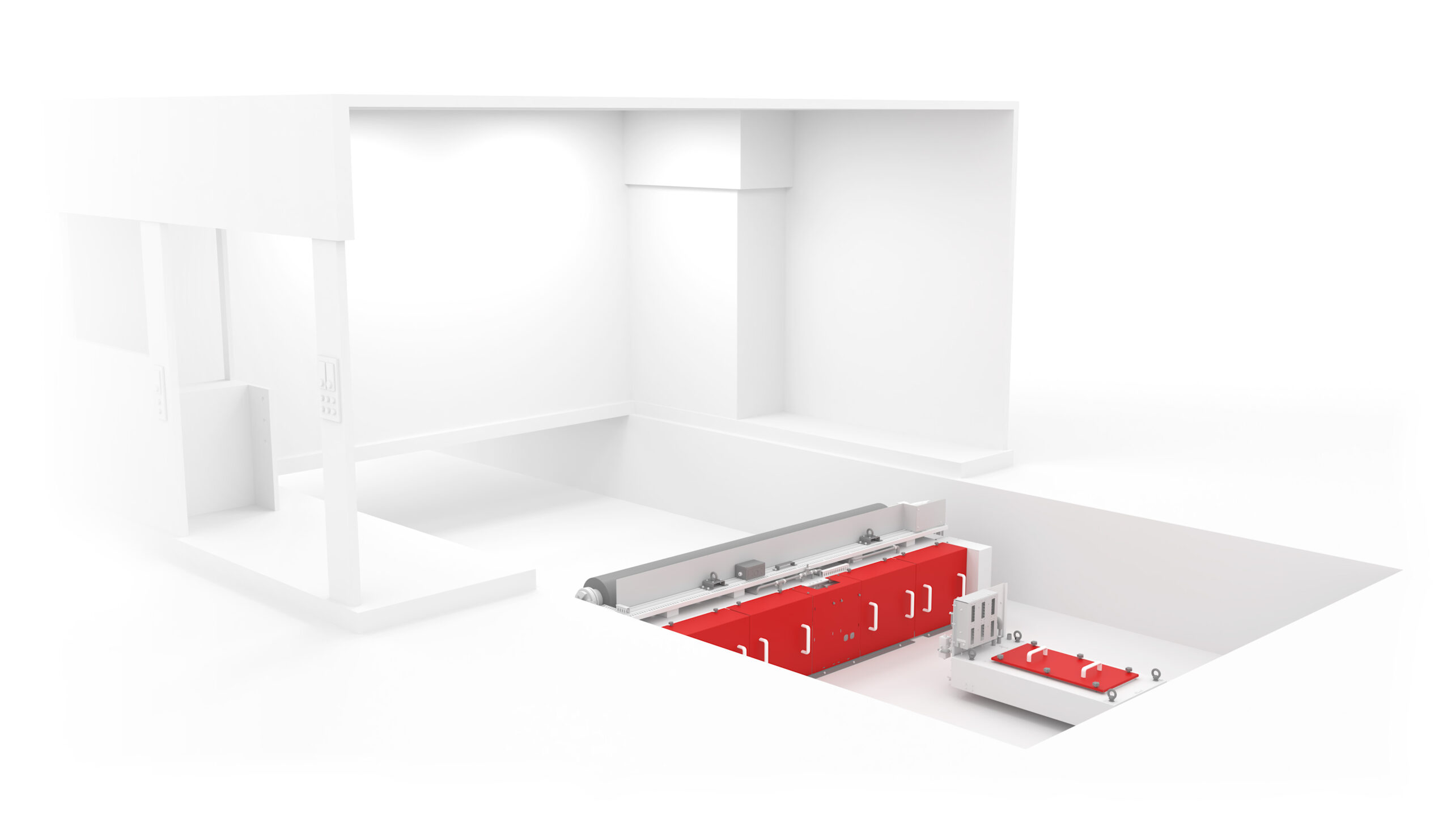

Sono Pit:

The power of Sono, now for your over-pit press

Over-pit presses with automatic anilox exchange capability can now benefit from the amazing impact of SONO cleaning.

We’ve reconfigured SONO to offer the same on-press cleaning benefit to your RDC line and clean your Anilox inventory whilst in production. With SONO Pit, your over-pit operation can experience exceptional cleaning results with zero downtime to boost your productivity.

Amazing savings with Absolute cleaning

See the impact of adding SONO into your ink circuit:

Number of units to clean

4 units

- 1

- 15

How many cleans per year

(Average per unit)6 cleans

- 1

- 24

contract cleaning

360,000 more boxes per year using SONO

€20,000 of productivity increase per year with SONO

in-house cleaning

1,080,000 more boxes per year using SONO

€54,900 of productivity increase per year with SONO

Calculations based on: Box output of 10,000 per hour. Contract cleaning cost of €500 per anilox @ 2 hours cleaning time for each roller. €500 machine capacity cost per hour.