2G Chamber: Performance

2G Chamber: Performance

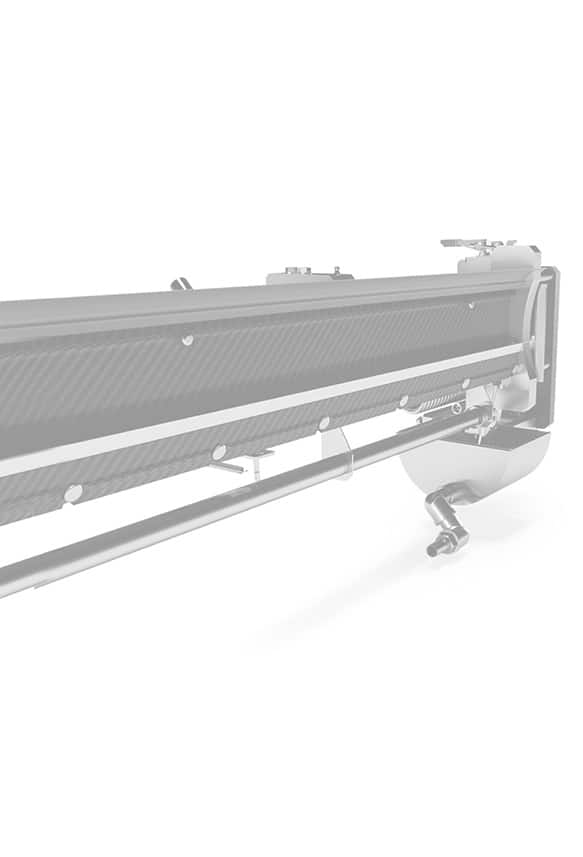

A blade change shouldn’t

hold you back

Reduce print unit downtime

Thanks to our tool-free blade clamp, one operator can change blades on a 108’/2750mm chamber in just four minutes. Less downtime for your printer, more productivity.

The evolution of blade removal

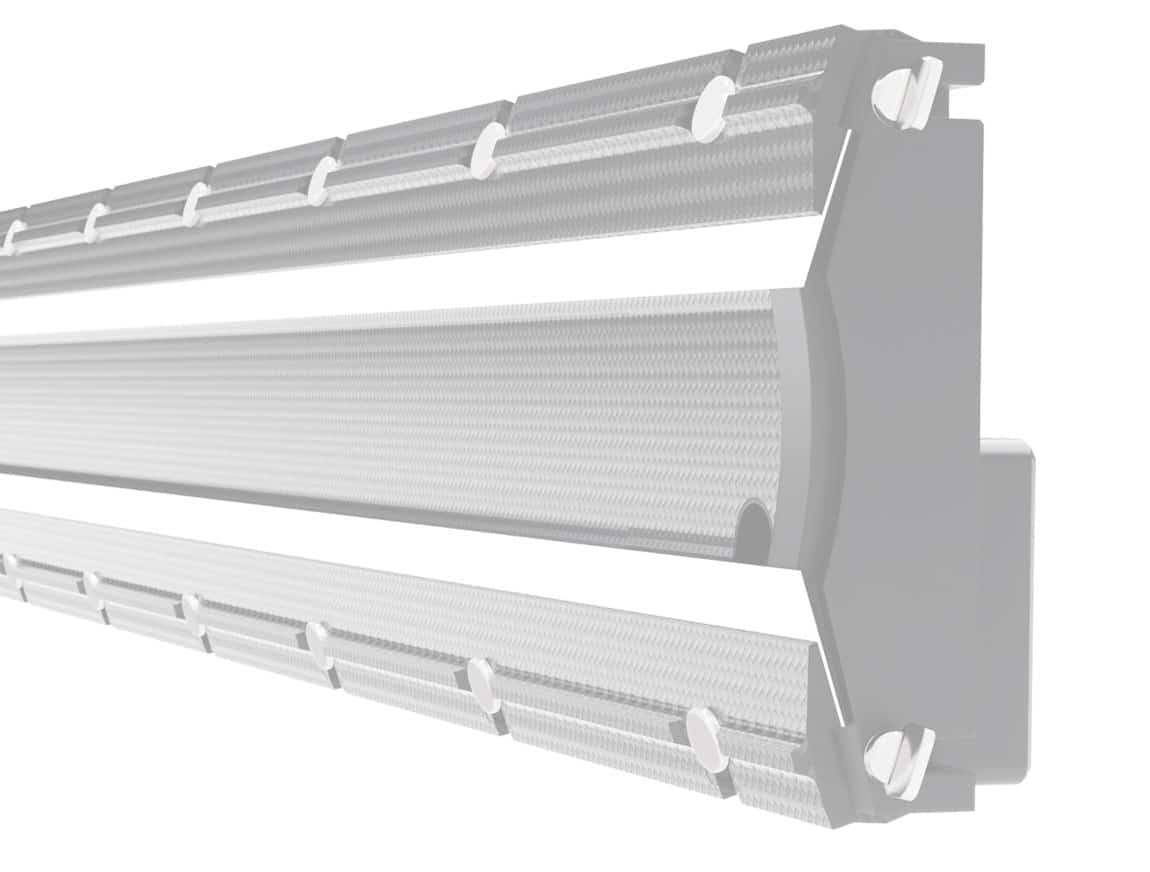

Tool & Allen Key

Fiddly, risky, slow, and prone to uneven torque causing rapid blade wear.

Wing Nut System

Quicker than tool & allen key, but still prone to human error and uneven blade wear.

2G System

Absolute’s quick-release system is less fiddly, measurably faster, maintenance free and totally reliable.

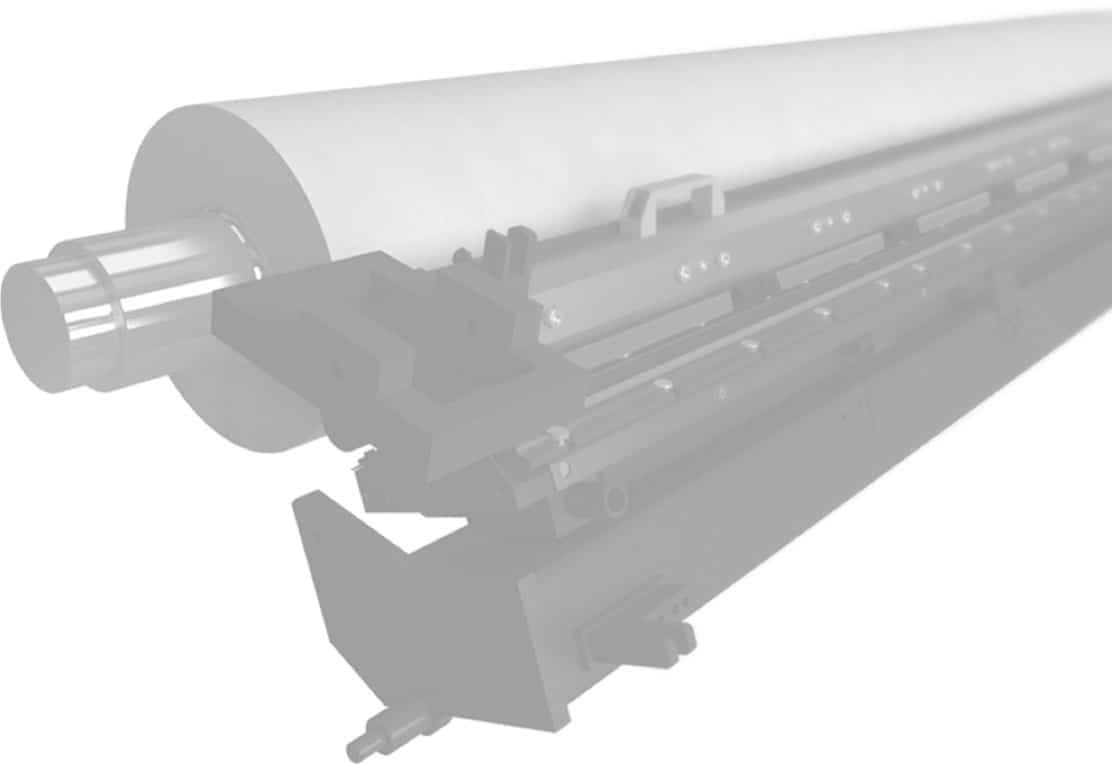

Unique vibrations damping construction

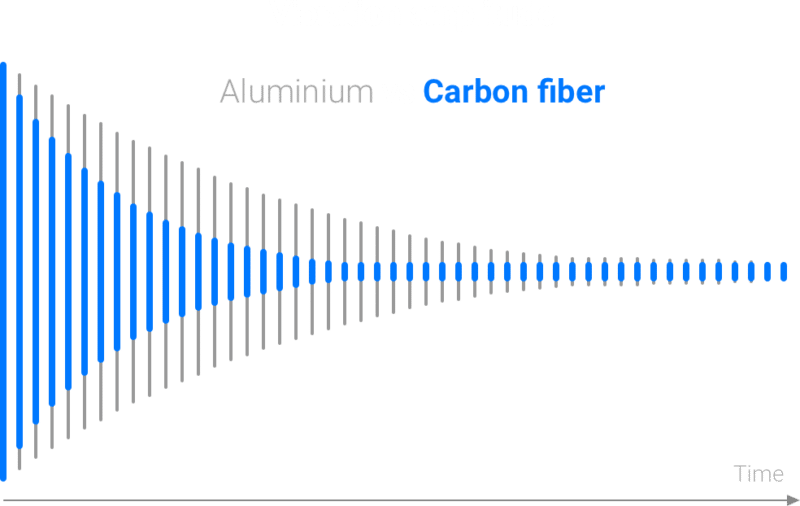

Flexo often suffers from vibration issues, partly due to the plate layout or to weakness in the actual unit design. Again, Absolute has provided the answer.

Our 2G chamber is specifically designed and built with carbon fiber, which absorbs vibration, allowing your unit to run faster without bounce or chatter and producing superb print quality at higher speeds.

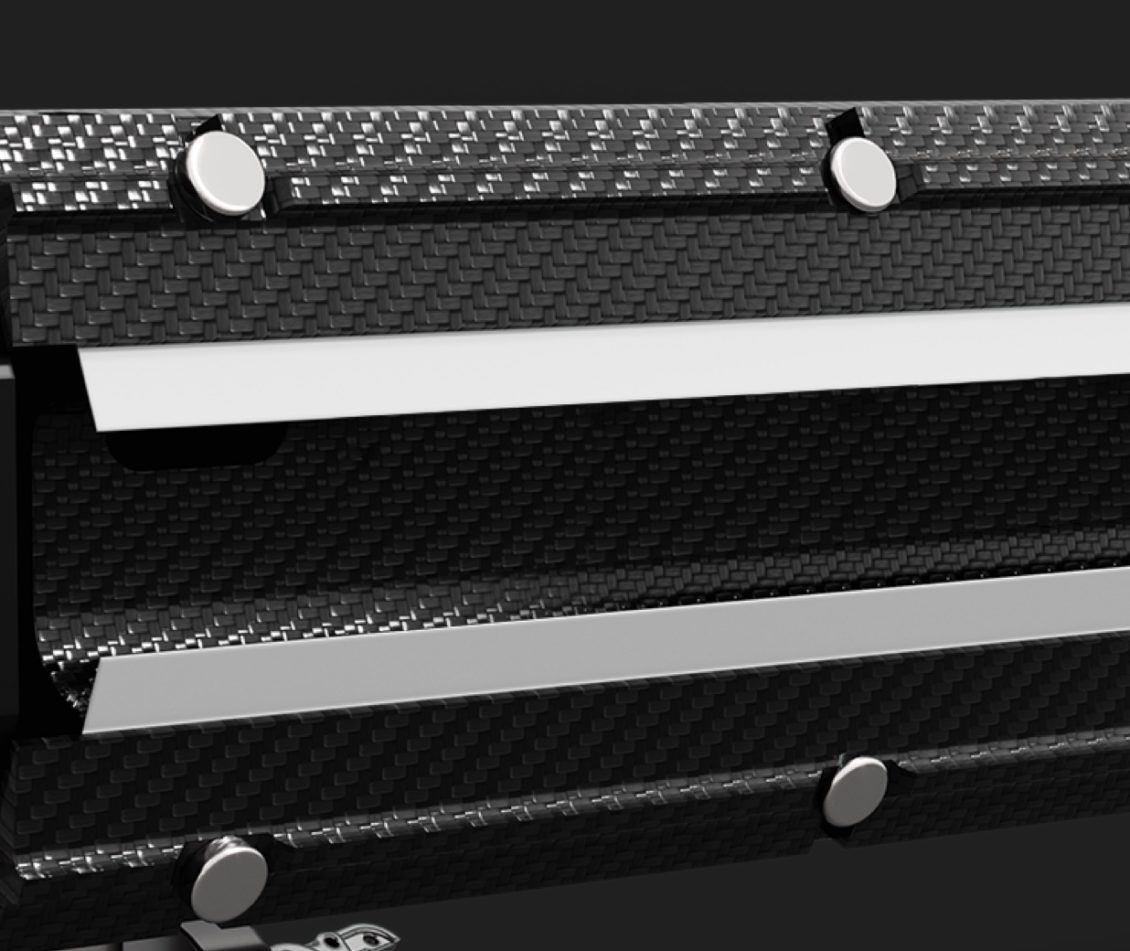

No twisting or warping

Plastic-moulded products such as nylon and UHMW don’t respond well to temperature changes or extremes. Aluminium chamber extrusions are eventually affected by stresses during use. The result is twisting and warping that makes an even wipe across the anilox impossible, causing a massive increase in rejected products and inevitable delays.

High density woven carbon-fibre is 300% stiffer than aluminium and isn’t affected by variations or extremes in temperature and unlike aluminium does not suffer with warp during use. So, you get consistent doctoring, regardless of your unit’s harsh operating environment or print volumes.