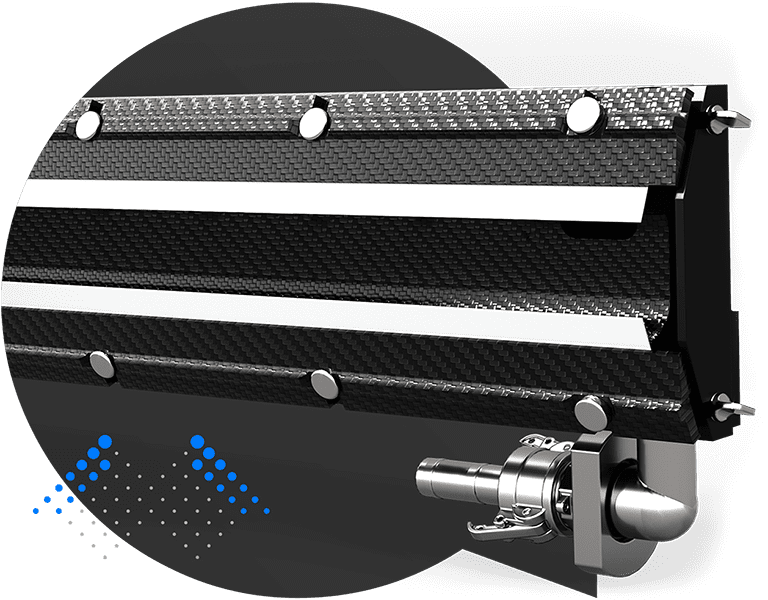

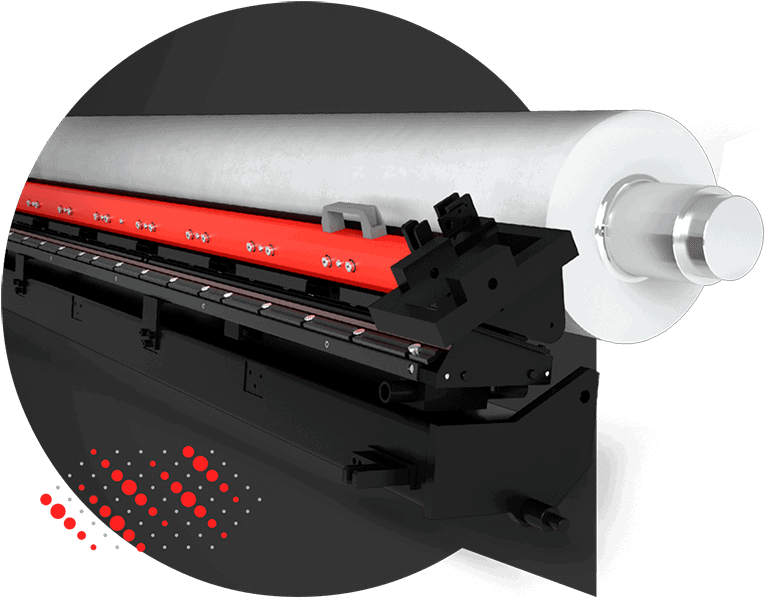

Absolute Engineering, the supplier of woven carbon fibre doctoring systems, has just announced a 25% increase in sales for the 12 month period to June 2010.

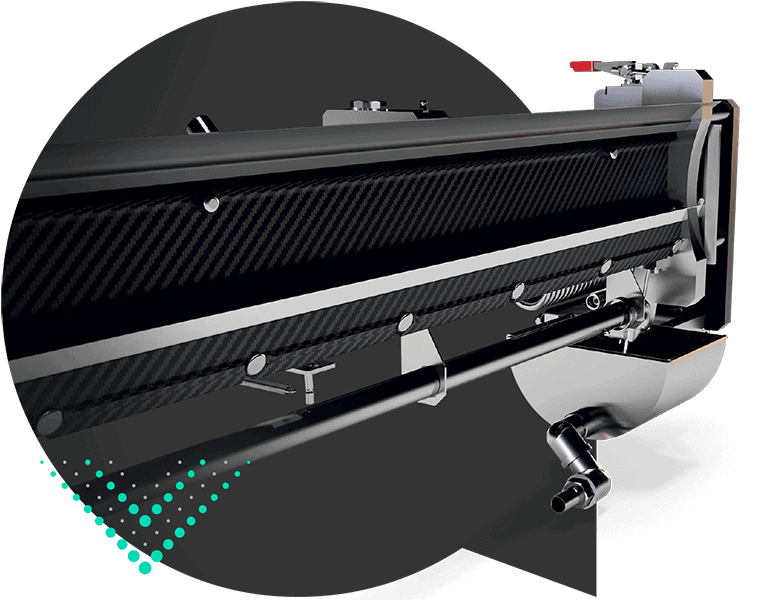

Growth has been achieved because of two major factors; firstly, Absolute concentrated on developing a “standard “range of upgrades for the most popular equipment such as BOBST, Ward, United, EMBA, Martin and Gopfert. This allowed the company to prove to potential customers that they had a successful track record with an identical machine.

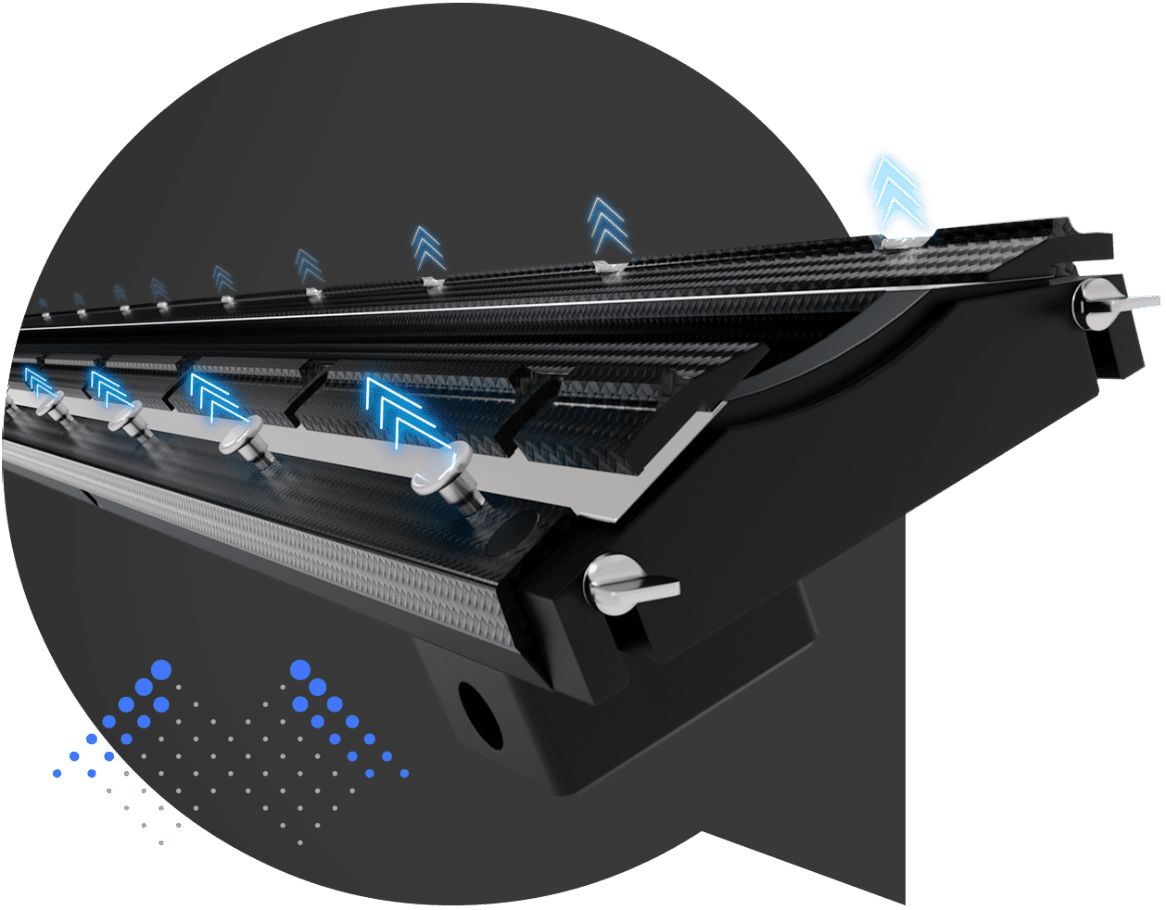

The second factor leading to the sales increase was new products such as the I-MAX ink saving system. Absolute has achieved major success with this, and have just completed another installation on a BOBST Masterflex, where the customer has seen a massive reduction in ink loss.

Commenting on the project Antony Whiteside of Absolute confirmed “I-MAX is ideal for customers who are focusing on short job runs, and clearly a lot of these customers have purchased Masterflex lines for this purpose. I-MAX allows them to achieve ink savings of around 85% compared to traditional chambers. The translation of this into real savings and a remarkable payback make it easier to justify, even when it is hard for plants to obtain funding”