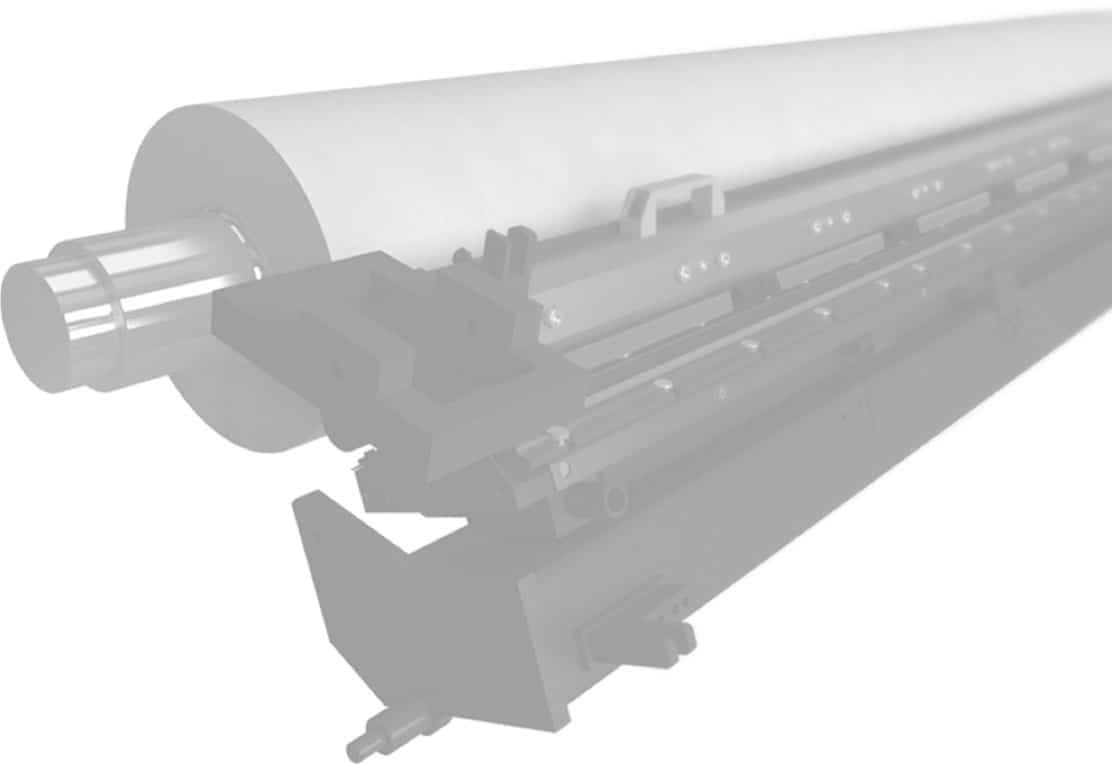

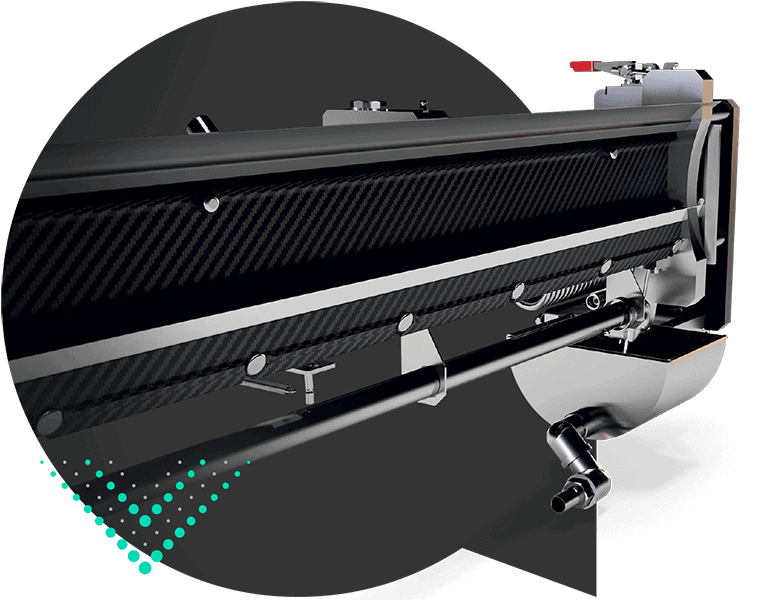

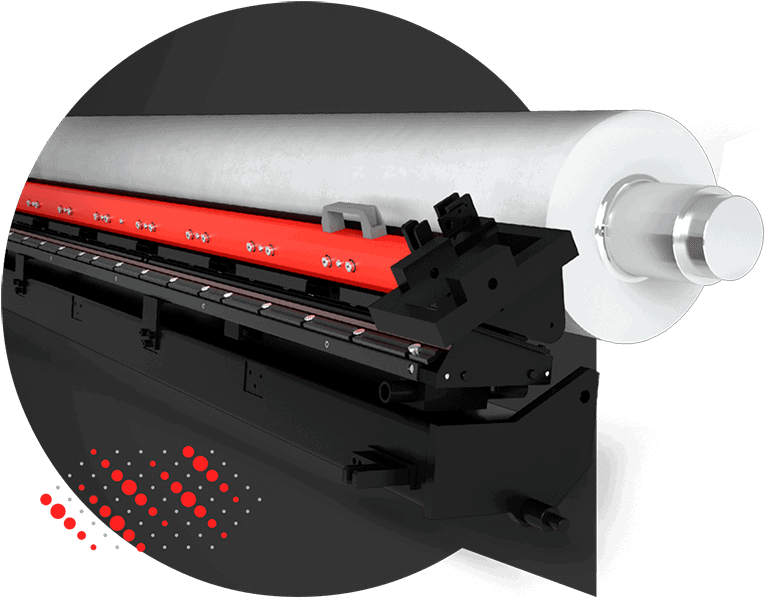

Absolute have recently converted a further two BOBST Bielefeld flexopresses to 2G Carbon Fibre chambers for client East Riding Sacks (ERS) – the UK’s premier manufacturer of paper sacks.

In addition to being the largest independent supplier of multi-wall sacks in the UK, ERS is also a key player in the European sack industry with a reputation for investing in high-quality equipment for both print and conversion departments.

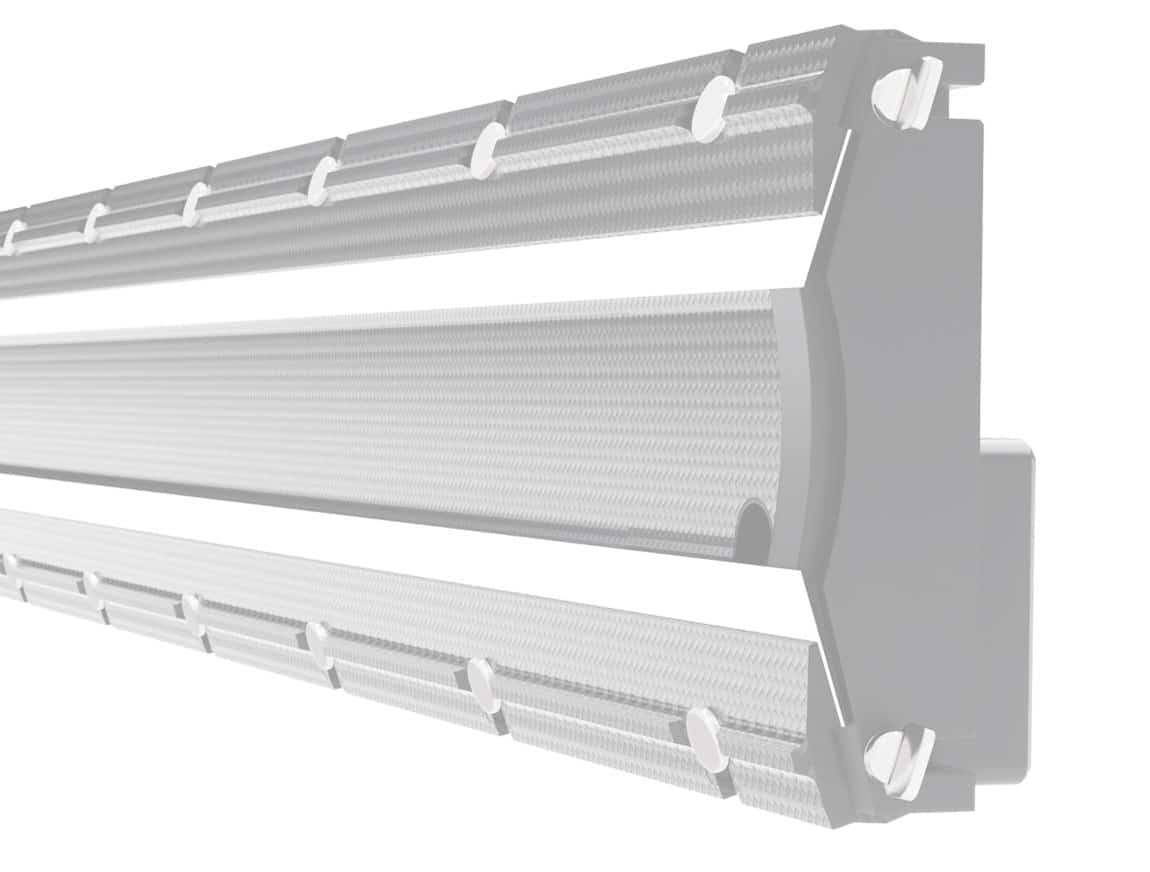

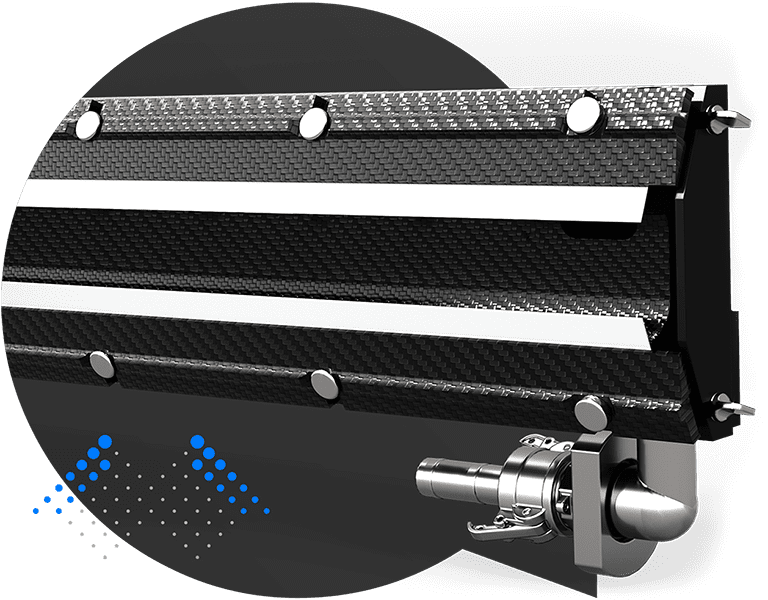

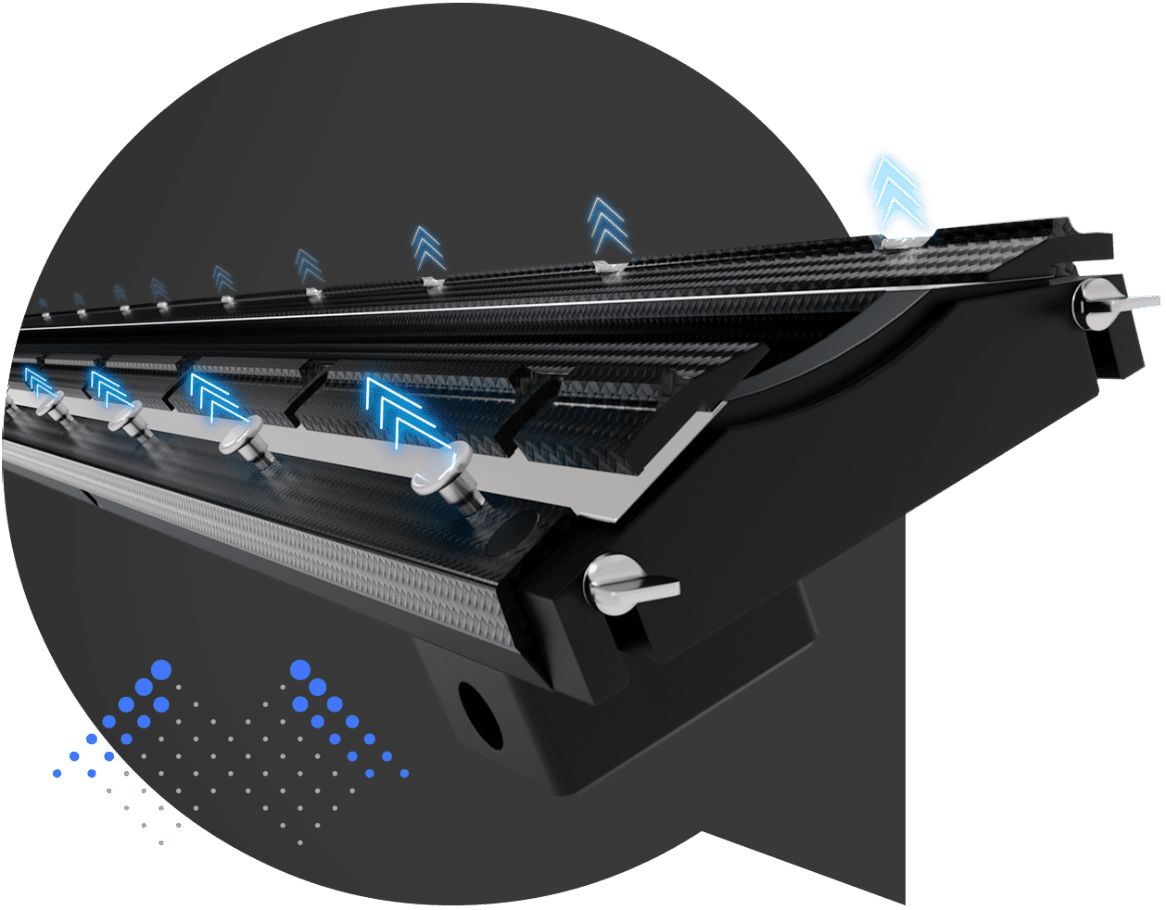

Their relationship with Absolute has developed since 2015 when they needed to replace the chambers on their 6-colour F+K 16S. As the existing systems were heavy and worn, ERS took the opportunity of this initial upgrade to enhance performance and improve the ergonomics of their press.

Jürgen Bopzin, East Ridings’ Technical Engineering Director, commented: “There are several suppliers of chambered doctor blades, and so we assessed the market alternatives, including the OEM alternatives and decided to try just one 2G Carbon Fibre chamber from Absolute.

“After a testing period, we reviewed the performance and found that it gave us significant improvements in press cleanliness, speed of blade change and ergonomics and, on this basis, decided to replace the remaining seven units. We are really happy with both the technical expertise Absolute offer, as well as the service and support they have given us since.”

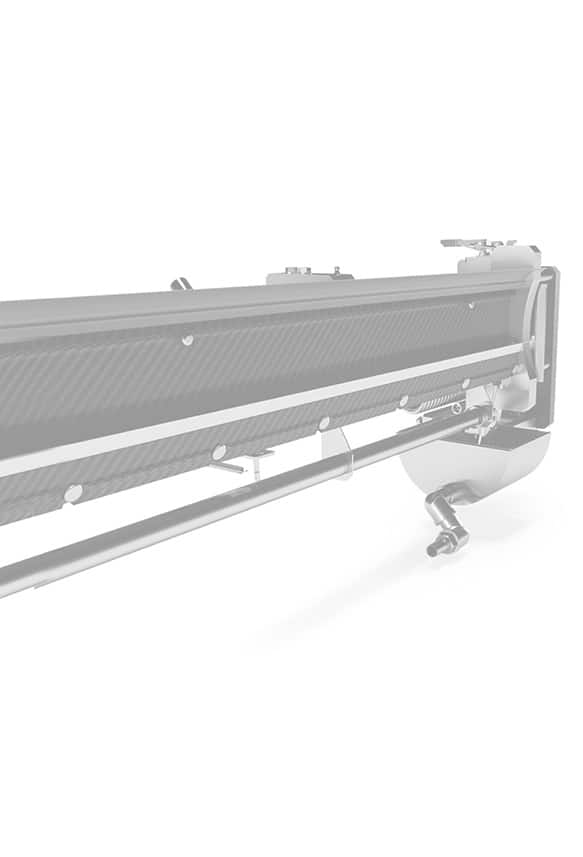

So great was the improvement in fact that, after several months, ERS decided they would also upgrade their 8-colour BOBST F+K 20SIX press, an installation now completed which has proved a similar hit with the operators and management alike.

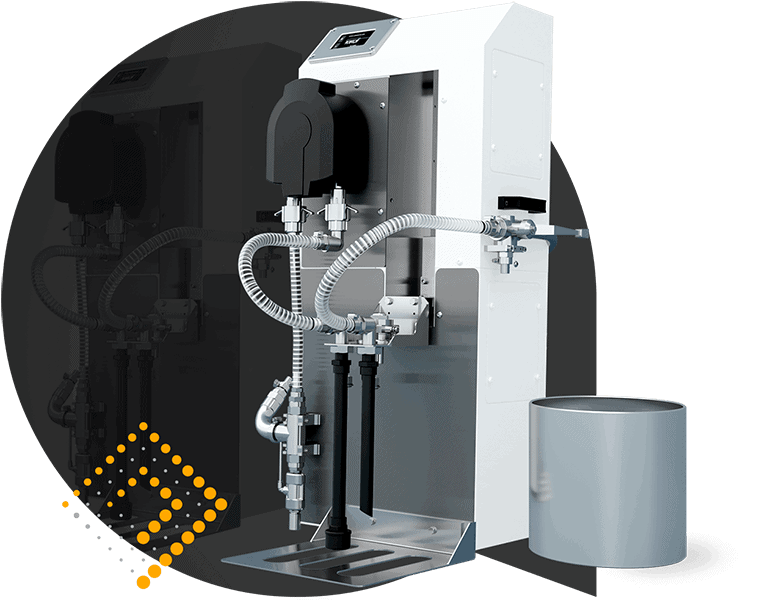

Antony Whiteside, MD of Absolute is also happy with the outcome. “ERS is a progressive company, constantly investing in new equipment but also putting significant effort into upgrading the performance of existing equipment. This partnership is a great example of how excellent results can be achieved when proactive, like-minded partners work together. Absolute follow this model for both upgrades and New Product Developments”.