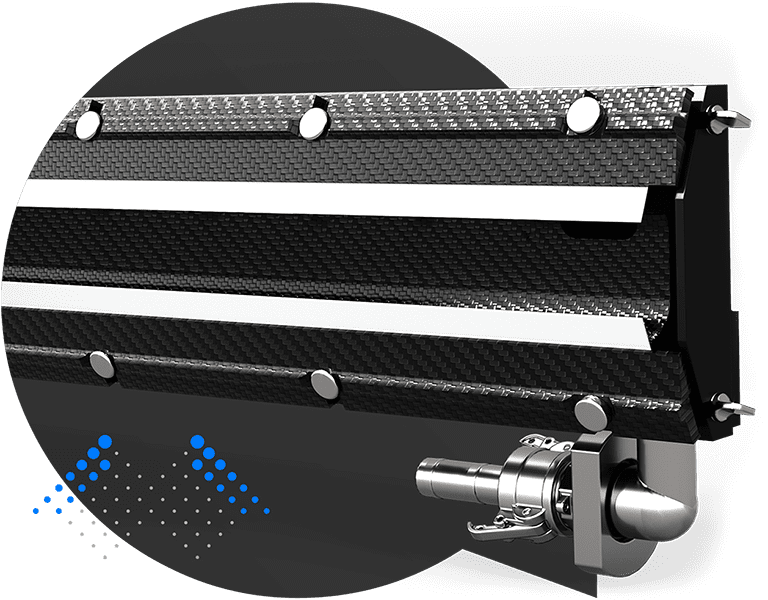

Five years after their first introduction to Absolute – creators of the most successful Carbon Fibre print chamber system available – global company Fardem Packaging is investing heavily in this equipment at their Edam site in the Netherlands. Not only are they upgrading existing machines, but installing Absolute chambers on new machines to make the plant one of the most efficient in its sector worldwide.

Fardem was established 125 years ago, long enough to gain a formidable reputation in heavy duty packaging predominantly for the chemical, fertilizer, animal feed and food industries. Innovators to the core, the company also manufacture specialised polythene films for the business-to-business sector and, in every aspect of their operation, focus on long-term partnerships with customers and suppliers such as Absolute.

Innovative though they are, for such a significant investment Fardem had to be sure both the upgrades and new machines were of the optimum standard. To make sure of this, when the project began in 2011, Engineering Manager, Ton Voorneveld bought one chamber each from several suppliers as an initial trial.

There was no contest – Absolute’s chamber far outmatched all rivals, resulting in a complete retrofitting of all Fardem machines. Since then, a further 20 systems have been supplied, bringing the total to 65 chambers to date.

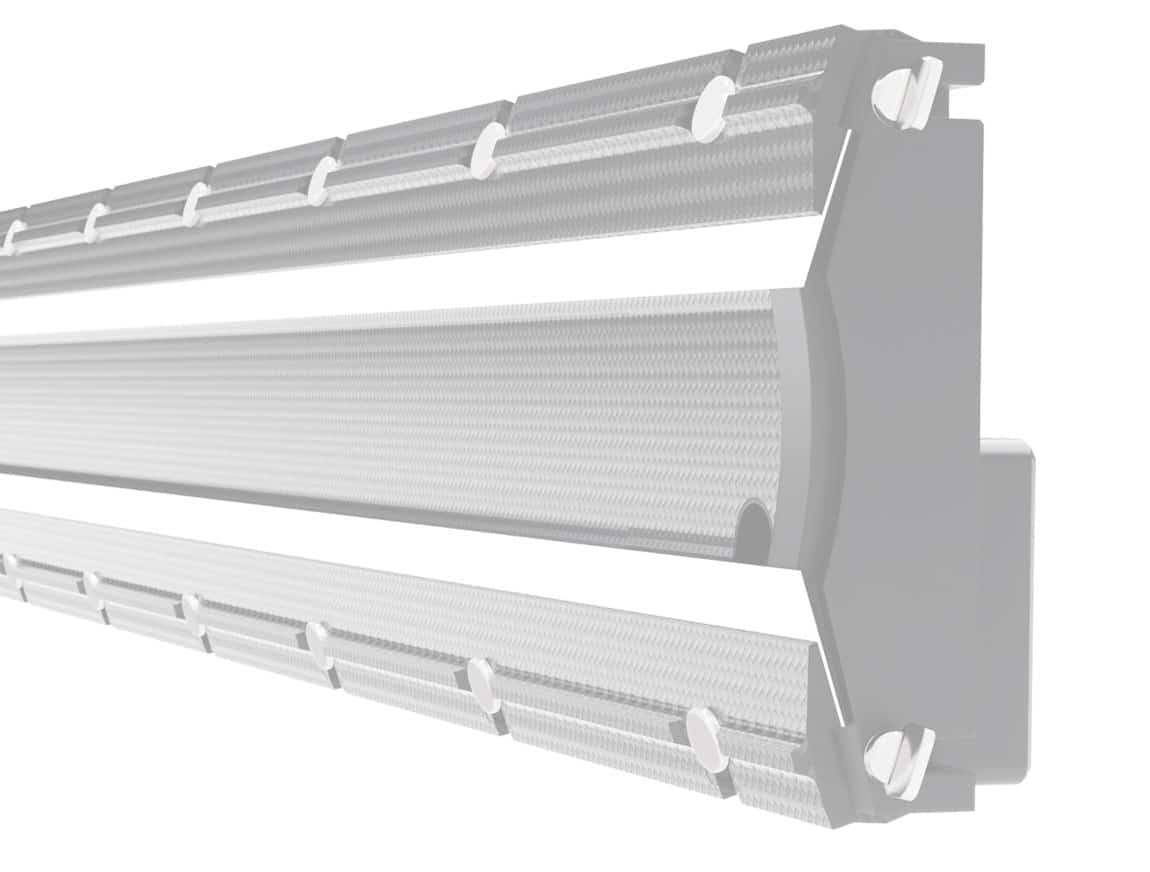

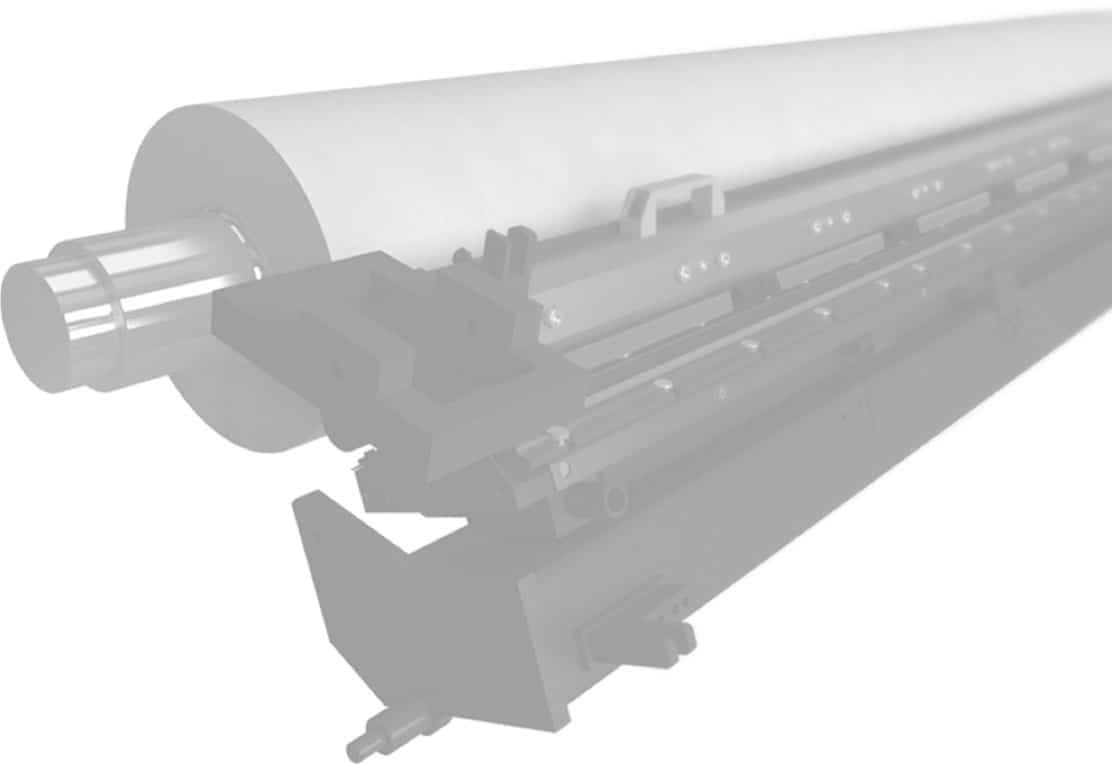

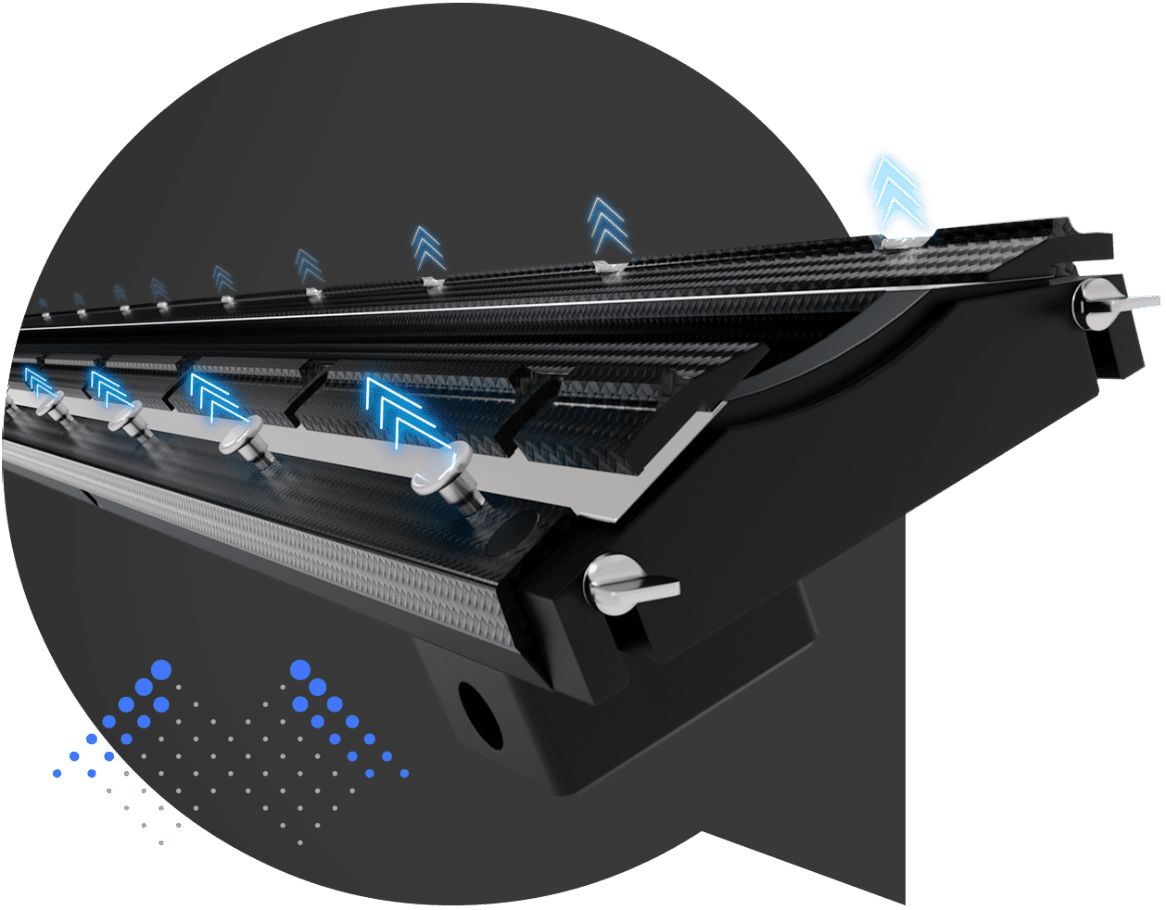

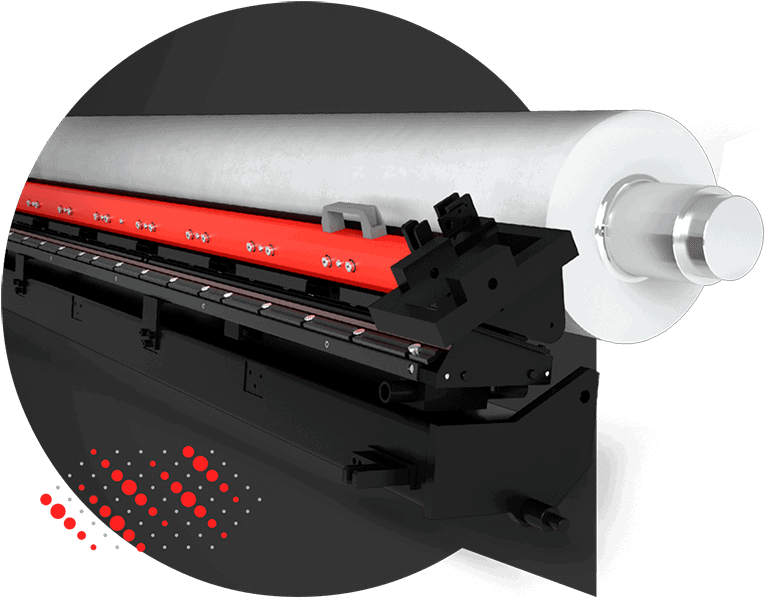

One of the reasons Ton chose the Absolute system was that, with 14 different chamber sections, they have the perfect profile – creating the optimum doctoring angle for each anilox roller. In addition, all Absolute chambers and assemblies were designed to be fully interchangeable, even when used on separate machines.

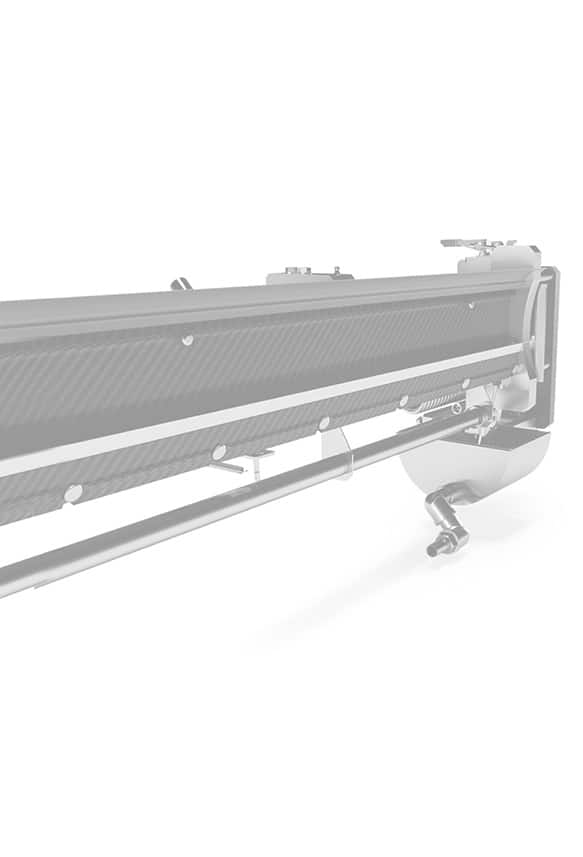

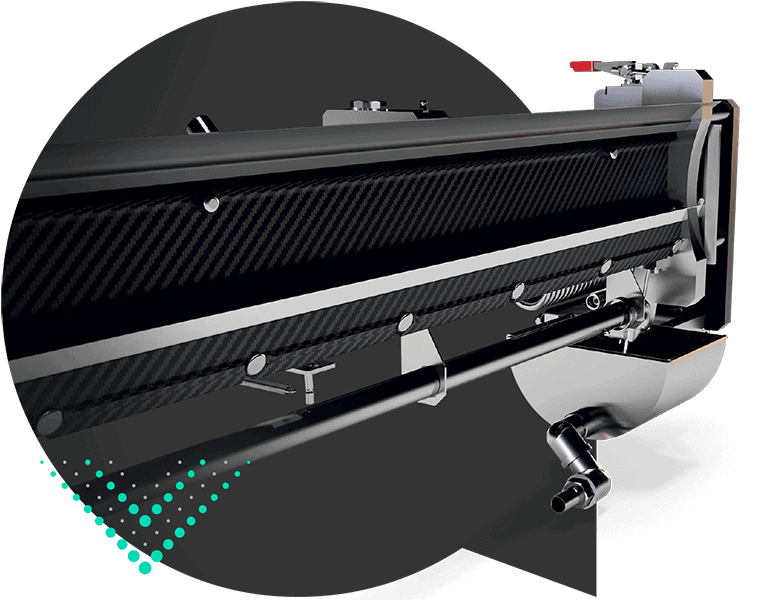

Ton also appreciated how Absolute could provide a bespoke loading system: “This meant we didn’t need to cut away at our existing print units, as the loading system accommodated them all.”

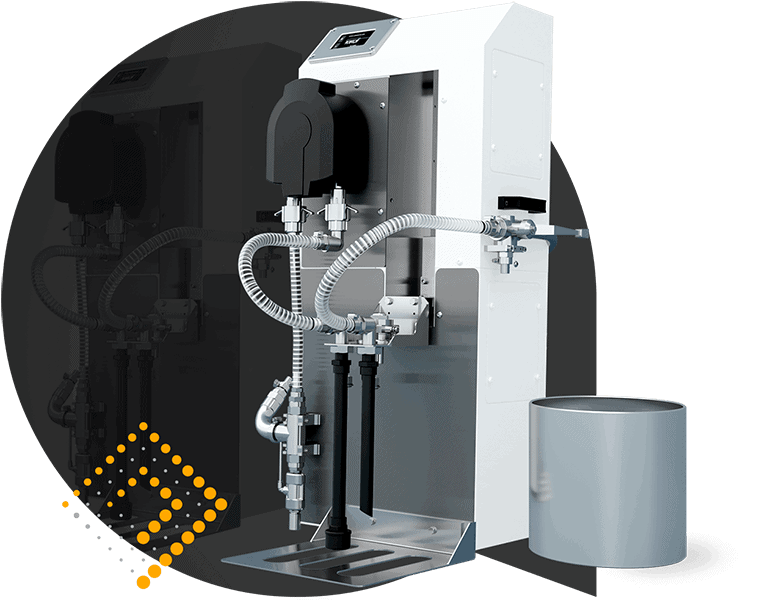

With an ongoing relationship in mind, Ton visited the Absolute plant in Huddersfield, UK in order to understand the experience and quality of Absolute’s operation and was highly impressed by the resources available for both manufacturing and after-sales services.

There have certainly been no complaints. Ton confirms that retrofitting Absolute chambers to 50 print units has “standardised set-up procedures and minimised our training requirements, so we can improve efficiency and consistency of production while the chamber itself has reduced wash-up times and minimised ink loss.”

Naturally, Managing Director of Absolute, Antony Whiteside, is proud of this assignment, which has been completed so successfully. “Although this is a large number of chambers, Fardem is a very typical customer in that the majority of our business involves trading over many years with the same customers placing repeat orders. Part of our strategy is to support customers, maintaining close, long-term relationships.”

Ton is also very happy with the outcome “I am very satisfied with the quality delivered. Absolute has achieved an excellent result and I congratulate everyone at Absolute for the high standard of product.”