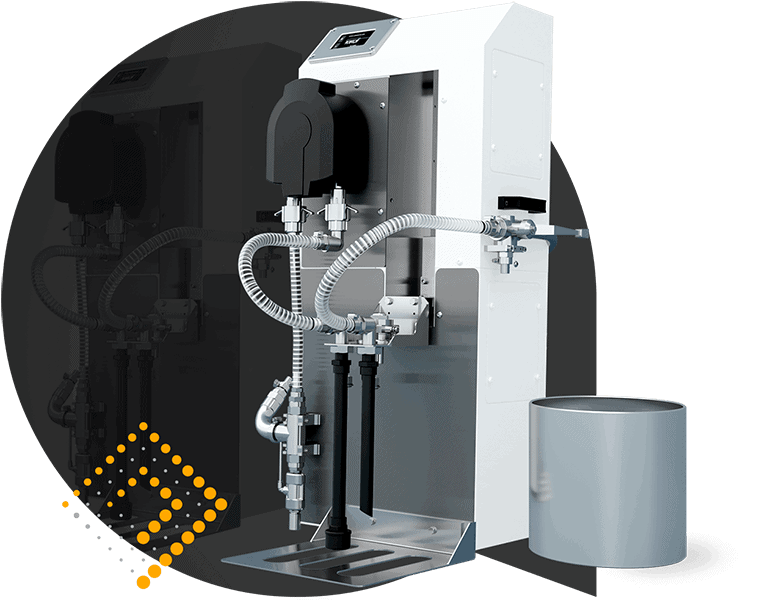

SAICA UK Thatcham and Absolute Engineering have completed a project to upgrade two BOBST 160 post printers.

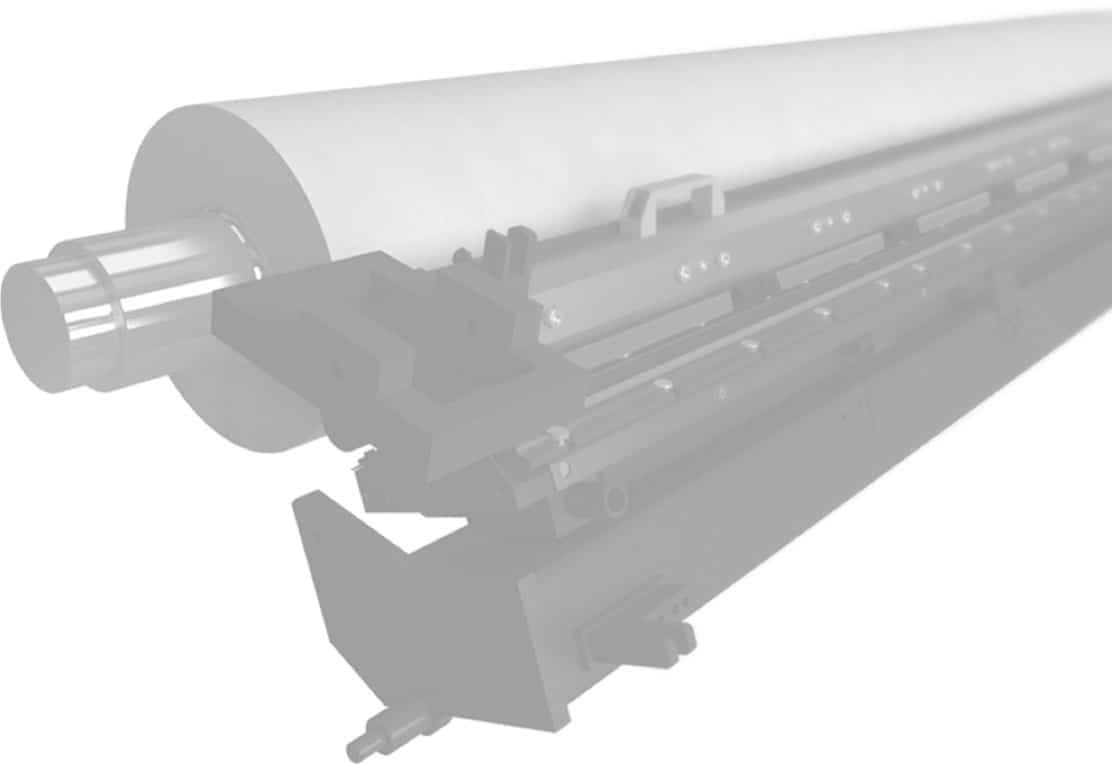

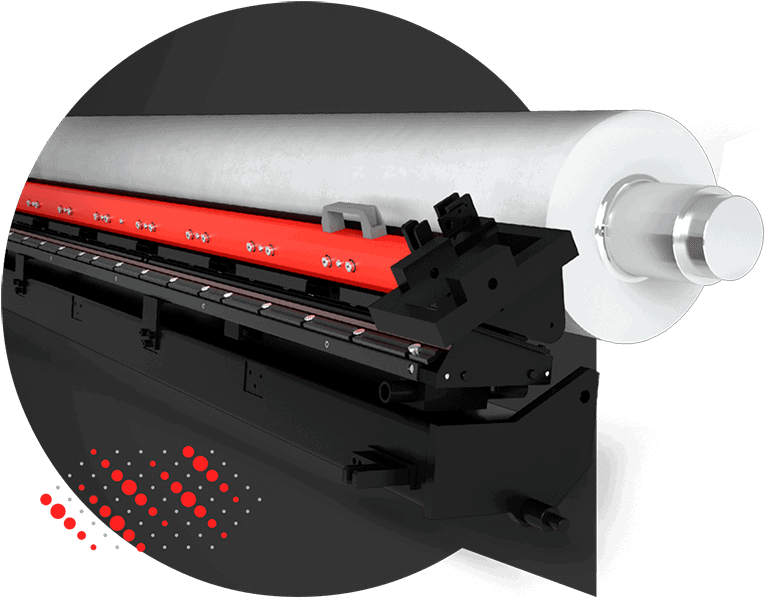

One line had existing aluminium chambers that were badly corroded, leading to excessive downtime and cleaning, whilst the second machine still had the original rubber roller system and did not produce the required print consistency.

SAICA approved the investment in order to improve both the quality of the print produced and reduce the downtime associated with a combination of an old inking system and the modern requirement of short order change times.

Ashley Bell of SAICA confirmed “This project is part of an ongoing plan to improve our efficiency and quality by optimising the performance of our existing equipment with specific upgrades.

We have worked with Absolute over several years, and have experience of both their products and their after-sales support, and so we were comfortable working with them on this important project. It’s clear that specifying Absolute was key to the project meeting the KPI’s we set ourselves”.

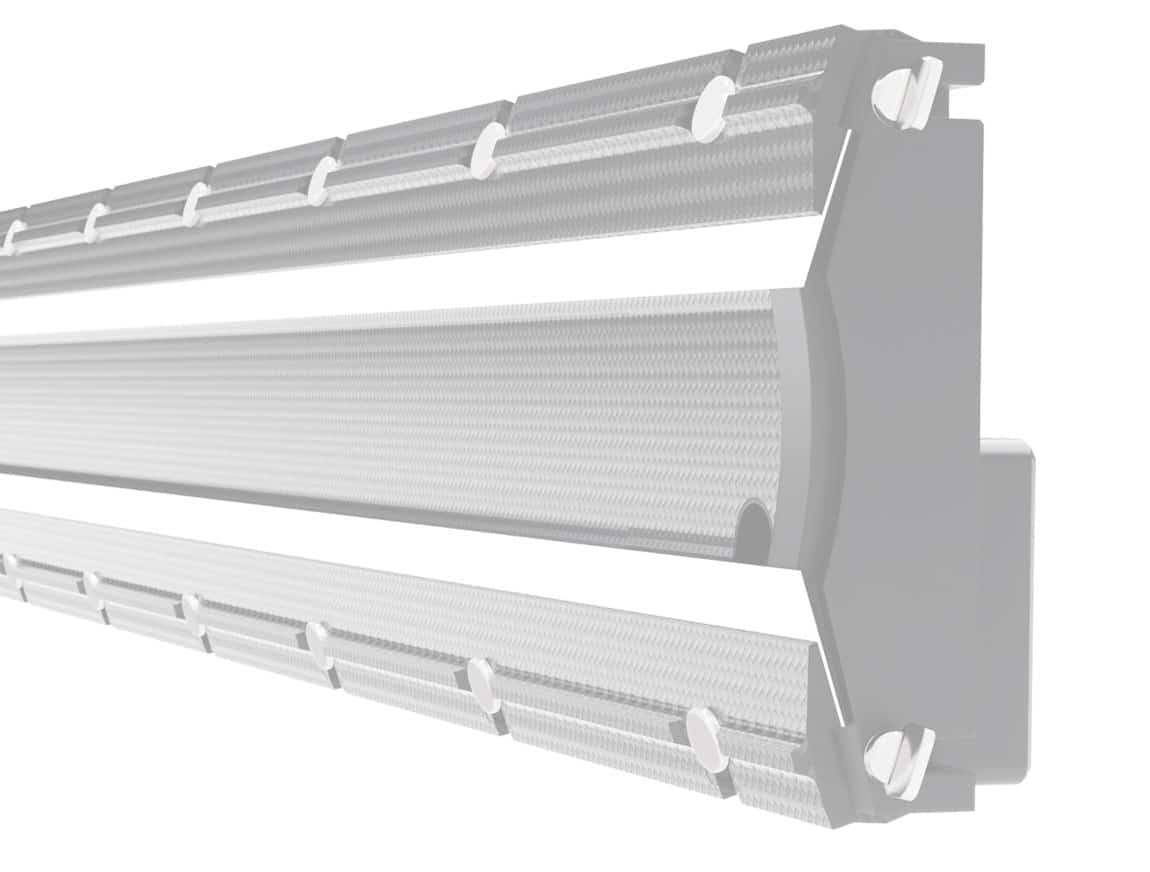

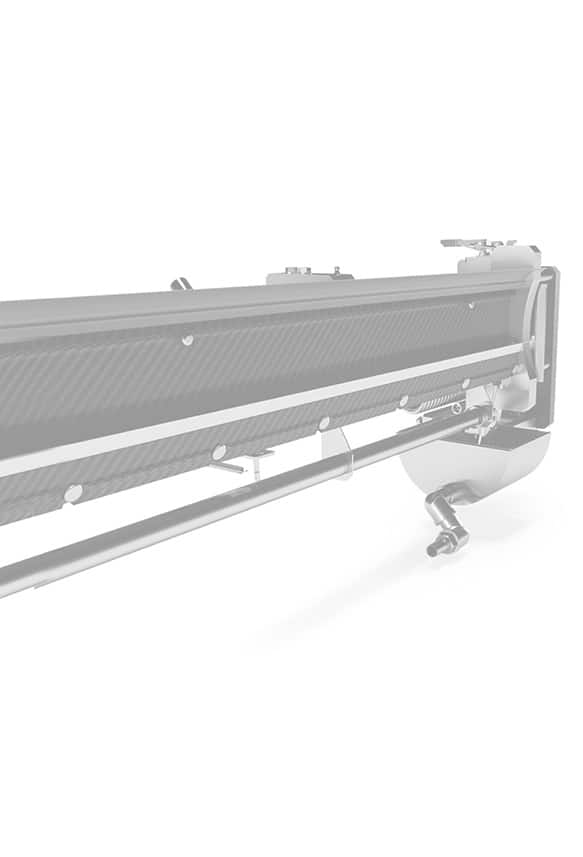

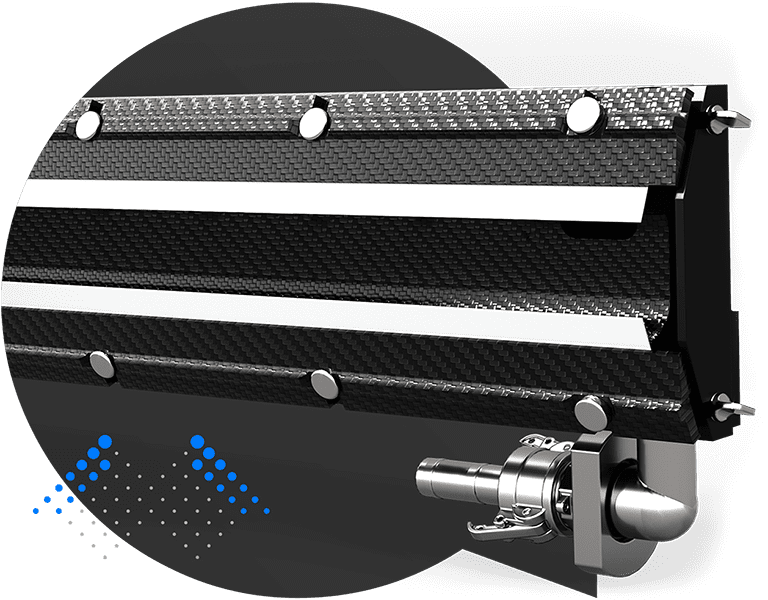

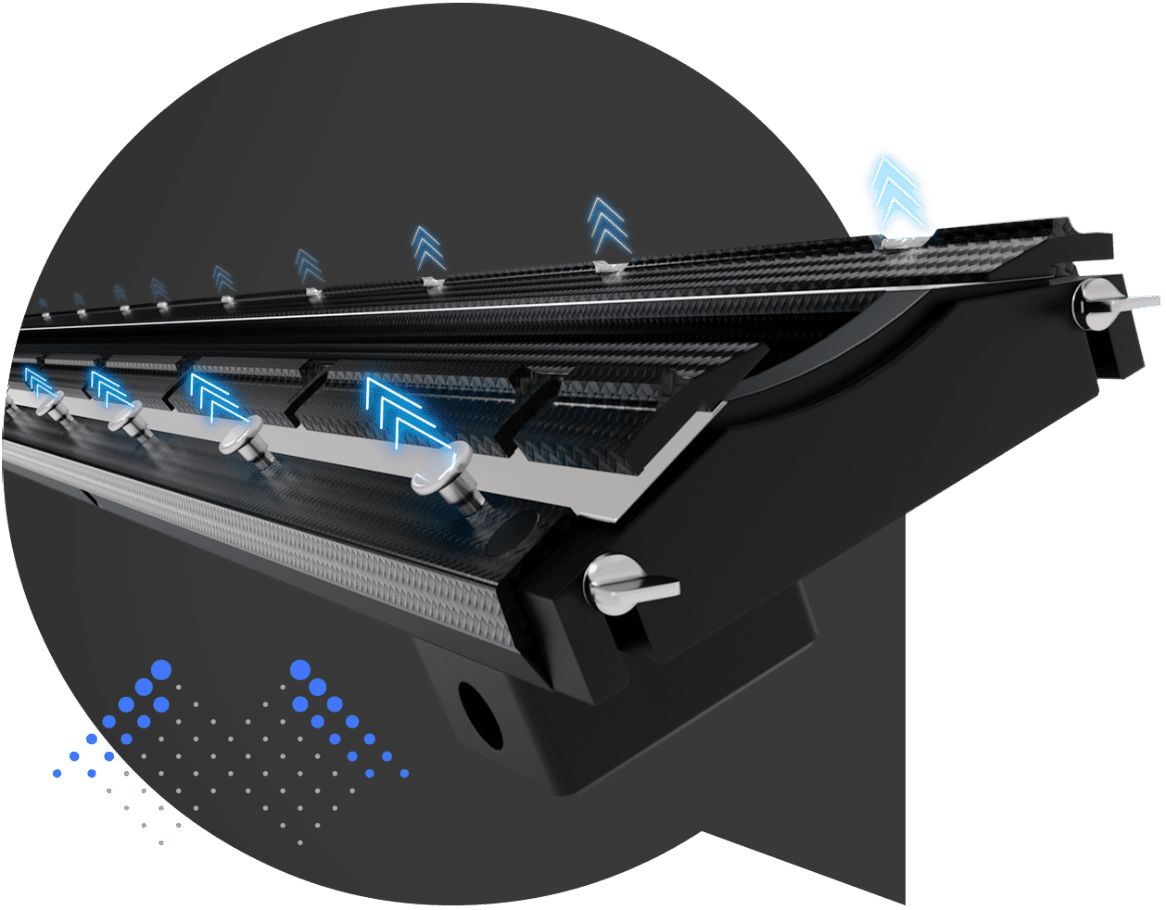

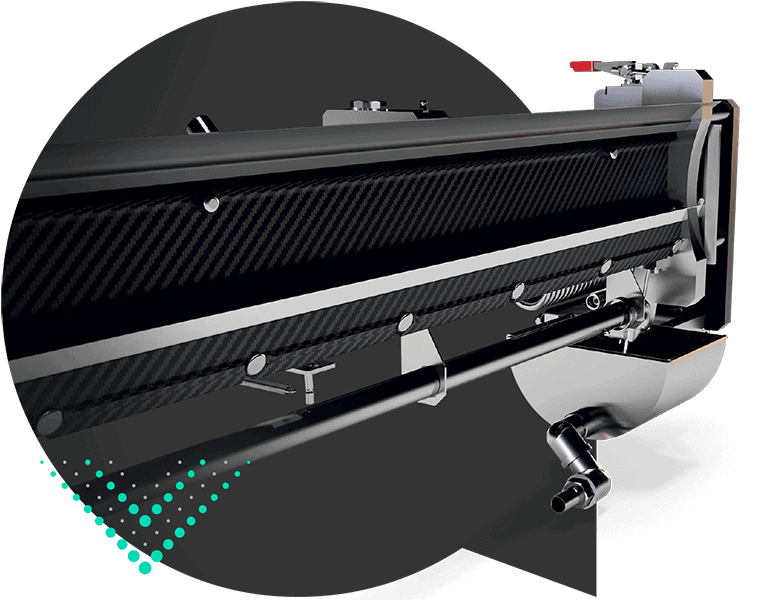

Absolute supply a range of woven carbon fibre doctoring systems to users of high-performance flexo printing equipment across the World. The products include the 2G dual blade system, the Uniblade single system, and the patented I-MAX ink maximising system.